Create Child MOs

This utility creates Child-MOs for each non-Phantom subassembly within the Picklist of a Parent MO. The utility can be run directly by providing “parent” MOs in an import, and it can also run automatically when manufacturing orders are created from the MO Entry window or from a Sales Transaction.

The Create Child MOs Import utility can be run using input from a spreadsheet or SQL table. See the Excel Map and Table Map sections below for more detail.

Create Child MOs can run automatically each time an MO is created by MOGen (i.e. such as when the Create MOs utility runs, and when Manual Entry is used). Enable this functionality by marking the Create Child MOs setting.

Create Child MOs can also run automatically when an MO is created from Sales Transaction Entry. In this case, the parent item is Make-to-Order (manual or silent), or it is a Configured item. When the MO is created from Sales Transaction Entry, the Create Child MOs utility will catch the parent MO and create Child MOs for the Make-to-Stock subassemblies. See the Setup chapter of the manual for instructions on enabling this feature.

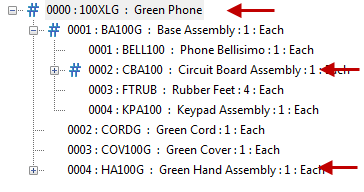

As an example of the Create Child MOs process, take an MO for 100XLG. The Bill of Materials for 100XLG is shown below. If BA100G is a Phantom, the utility would create MOs for HA100G and CBA100.

However, if BA100G is not a Phantom, the utility would create MOs for BA100G, and HA100G, then it would read the Picklist for the BA100G Manufacturing Order, which would cause it to create an MO for CBA100.

When Create Child MOs runs automatically after a parent MO is created in GP, the MOGen Status window will open. This window shows what the utility is working on while it creates MO. The utility may run for many minutes depending on the number of “make” assemblies, the size of the Bills of Material, and the depth of the Bills of Material.

In addition to creating the Child-MOs, proper scheduling requires that the top-level be scheduled first so GP Manufacturing can calculate the correct Start Date and Start Quantity. The Child-MOs are scheduled so that their End Date is the Start Date of the Parent MO. Also, the Child-MO End Quantity is set to the Start Quantity of the Parent MO (this ensures that a Shrink Factor on the Parent flows down to the Child MOs), and the Post To Site of the Child is set to the Draw From Site of the Parent.

The Child Due Dates can be adjusted by Lead Time Offset. If the Use Component LTO option is marked on the MOGen window, the Due Date for the child MOs will be adjusted based on the number of LTO days and the “Offset From” setting for the component on the parent item’s Bill of Materials.

![]()

LTO can be a positive or negative value. If the Start Date for the Parent MO is June 3rd and the Due Date is June 5th, the LTO Days and Offset From setting will have the following effect on the Due Date of a Child MO:

| Lead Time Offset (DAYS) | Offset From: MO Start Date | Offset From: MO Due Date |

| -2 | June-1 | June-7 |

| 2 | June-5 | June-3 |

LTO is subtracted using “Up Days”. If the Shop Calendar specifies Saturday and Sunday as down days, they are not included when offsetting an MO for the LTO. This is different than how GP Manufacturing normally schedules as it simply subtracts the LTO days from the Start Date, and only adjusts the resulting date if it falls on a Down Day. MOGen subtracts “working days” from the Start Date, so it will take into account weekends and holidays.

MO Generator always uses Backward Infinite scheduling when creating Child MOs. The selected Due Date for the Parent, and calculated Due Date for Children, is always validated against the Work Center Calendar for the Work Center on the last sequence of the routing for the item. If the Due Date falls on a down day, it will be adjusted backwards by 1-day until MO Generator finds an open day.

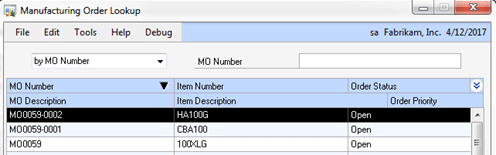

The MO Numbers for all of the linked MOs are based off the Parent MO Number.

As shown above, MO0059 is the top-level Parent, and all Child-MO will be numbered sequentially after that: MO0059-0001, MO0059-002, etc. The MO Description for the Child MO will contain the Parent MO Number.

For example, creating the Child MOs for 100XLG would result in the following list of MOs, where the MO Description of each child references the Parent-MO above it.

IMPORTANT: Because MOGen uses “-xxxx” to denote a Child MO, you should not use dashes in your normal MO Numbering sequence.

See the Exclude Items chapter for information about how to keep the Create Child MOs utility from creating MOs for certain items.

The Parent MO and its Children call all be rescheduled together by rescheduling the top-level parent. See the Setup chapter for more information on enabling this option.

MOGen will also attempt to delete Children when the Parent is deleted. When you delete the parent, you will be asked if you also want to delete the children.