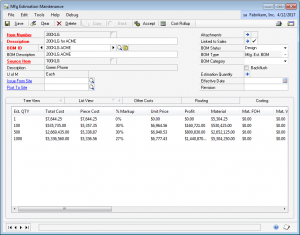

Engineer to Order (ETO) produces a Manufacturing Estimation (ME), which is the estimated cost to produce an item to a customer’s specifications. The ME is comprised of an Estimation BOM, Routing and list of Miscellaneous Costs. A tight integration to GP Manufacturing allows the ETO module to begin an estimate by importing an existing GP Manufacturing BOM and Routing, and when the ME is accepted, the ETO module transfers the ME BOM and Routing into GP Manufacturing, and creates new part numbers as needed. If the ME is linked to a Sales Quote Line, Accepting the ME can also update the Cost and Price on the sales line and change the item from a non-inventory item to a Sales Inventory item.

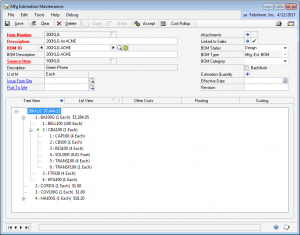

A new Estimation BOM can begin as a copy of an existing Manufacturing BOM or existing Estimation BOM, or it can be created from the ground up. When copying from an existing GP Manufacturing BOM, an snapshot is taken of the entire exploded BOM so that any component at any level can be tweaked as needed on the estimate.

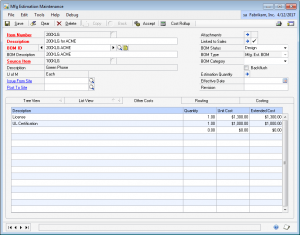

Capture other anticipated expenses, such as laboratory testing, licenses, or certifications, which will be required to produce the item.

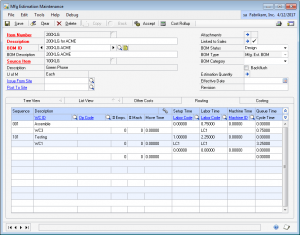

Like the Estimation BOM, the Routing can be created by copying an existing GP Manufacturing Routing, and Estimation Routing, or building the Routing from scratch. The Routing-Component linking capability allows the user to build an Estimate by starting with the Routing. As production sequences are added to the Routing, the materials needed at each sequence are linked to the sequence. The ETO module automatically builds the BOM from the list of linked components.

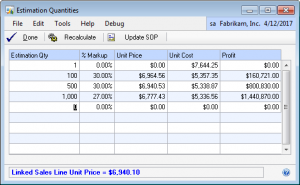

The estimate can be calculated for an unlimited number of user-defined production quantities. The Price can be calculated using a Percent Markup, or a Unit Price can be manually entered.

ETO performs a complete roll-up and revalue process on each ME BOM, where it starts at the lowest level of the BOM and recalculates the cost to manufacturing using the material, miscellaneous costs, and labor and machine costs, as well as Shrinkage, at level in the selected ME BOM.