Customization CR1196

MFG Auto-allocation from Multiple Bins

Description of Need:

When Manufacturing Allocates inventory it does so only from the Default Material Issue Bin set up on the Item-Site. If there is not enough inventory in that bin, the user must manually select one or more bins to meet the required quantity.

ACME would like manufacturing to automatically allocate from an many bins as needed, provided their business logic described below.

- If the Site ID is not 0FI (zero F i ), use the default Item-Site Material Issue Bin.

- Bins starting with “2-“

- Bins starting with “3-“

- Bins starting with a letter (A-Z) but not those starting with A, B, C, D, NW or RTL

- Bins starting with a number (0-9)

- Bins starting with A, B, C or D

- Bins starting with NW

- Bins starting with RTL

In all cases a bin “starting with” “A” can also just be “A”. So “starting with A” would retrieve A, AGG, A-123, and so on.

The rules should be processed in order. First try to allocate from “2-“ bins, then if more inventory is needed (or there are no 2- bins with inventory) check the 3- bins, and so on. For each rule, if there are multiple bins with inventory (i.e. there are multiple 2- bins with inventory), allocate by starting with the smallest quantity first (this should drive the system to consume small quantities thereby reducing the number of bins containing few items).

Description of Solution:

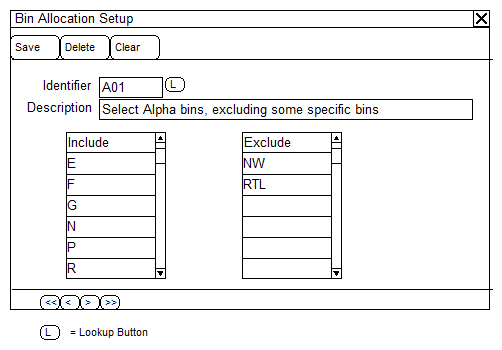

Navigation: Tools >> Setup >> Manufacturing >> Bin Allocation Setup

This window is used to define “rules” that govern how Manufacturing will locate bin inventory to allocate.

| Field | Function |

| Identifier | Use a naming convention that considers the following. (1) Rules will be processed in Alpha-numeric order. Use a naming convention that ensures the rules are processed in the desired order. (2) Using a naming convention that leaves space between Rules so that additional rules can easily be added between them. For example, A01, B01, C01, etc allows adding A02 so it falls between A01 and B01. |

| Description | Plain text description of the rule |

| Include list | Bins will be included if the Bin begins with, or equals, the specified value. For example, entering “2-“ will retrieve Bins such as 2-A, 2-B and so on. One ore more values is REQUIRED in the Include List. |

| Exclude list | Bins will be excluded if the Bin begins with, or equals, the specified value. The Exclude List may be empty. |

As shown above, all Bins beginning with “N” will be excluded, except those beginning with (or equal to) “NW”.

The Manufacturing module allocates inventory using a stored procedure called mmopAllocateBinQuantities. WilloWare will create a modified version of that stored procedure that will use the Bin Allocation Rules to direct how inventory is allocated.

mmopAllocateBinQuantities is used to allocate inventory in bins from several locations in Manufacturing, so the proposed change to that stored procedure will affect allocation from the following windows:

- Manufacturing Order Close

- Manufacturing Component Transaction Entry

- Edit Manufacturing Order Status

- Quick MOs

- Manufacturing Order Receipt Entry

- Picklist

Assumptions/Requirements:

- The functionality described above will not work with eConnect, any software that uses eConnect, or any software that directly writes to, updates, or deletes from SQL tables.

- The functionality described above is intended for the GP Desktop client.

For information on this design, or any other WilloWare customization or product, please contact us: