DS0784

Automatic Update Labor and Cycle Time on Routing Sequence

Historically, Acme has setup item routing values for Labor Time and Cycle Time in Dynamics GP when a product is commercialized. The Senior Cost Accountant at Acme has received numerous requests to troubleshoot cost/margin issues and improve overall accuracy of the cost to manufacture.

Over the past year, she has rolled out Data Collection in GP to track time to complete manufacturing orders, which she then uses to calculate actual labor values. The calculation and reentry process for labor values has been a tedious process, and is generally only executed when there is a problem.

As a proactive approach, Acme would like to invest in a customization/product that could aid in generating regularly updated labor costs. This application would pull a given set of data collection information for the prior 12 months, calculate, assess and either apply the update to each routing sequence or flag the routing sequence to review based on a threshold.

Design Features

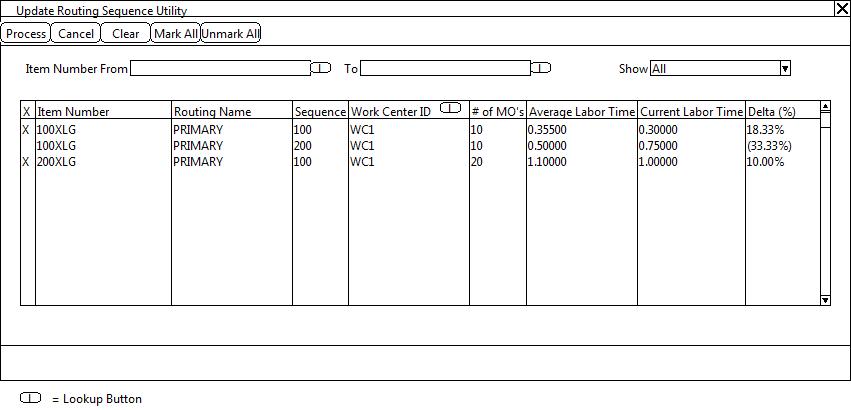

Update Routing Sequence Utility

Navigation: Utilities-Manufacturing-Update Routing Sequence Utility

This window is used to view and update Routing Sequences’ Labor Time and Cycle Time as well as its Work Center ID. The scrolling window will automatically populate when the window is opened. Only Item Number/Routing Name/Sequence combinations that match all of the following criteria will be displayed in the scrolling window:

- At least one Manufacturing Order (MO) exists with a Due Date in the last 12 months for the Item Number/Routing Name combination.

- The MO status is Complete or Closed.

- Actual Labor Time was entered for the MO/Routing Sequence combination.

For instance, if the Update Routing Sequence Utility window was accessed on August 4, 2018, the scrolling window would automatically populate with detail from Complete and/or Closed MO’s with a Due Date from August 4, 2018 through August 4, 2019.

| Field | Function |

| Process Button | The user will click the PROCESS button to update all marked records in the scrolling window.

Name/Sequence combination with the value entered in the Work Center ID field. |

| Cancel Button | The user will click the CANCEL button to exit the window. |

| Clear Button | The user will click the CLEAR button to clear the Item Number filter and refresh the scrolling window. |

| Mark All | The user will click the MARK ALL button to mark all records displayed in the scrolling window. |

| Unmark All | The user will click the UNMARK ALL button to unmark all records displayed in the scrolling window. |

| Item Number From | To filter the scrolling window on an Item or range of Items, the user will enter or select an Item Number from the lookup. This is the beginning of the Item Number range. |

| To | The user will enter or select an Item Number from the lookup. This is the end of the Item Number range. |

| Show | The user will select an option from the dropdown. The dropdown will default to “All.” Options include:

If records are marked, and the user changes the Show dropdown, all work will be lost. The user will be warned prior to updating the scrolling window. |

| X | This is a checkbox. The user will mark a record by checking the checkbox. |

| Item Number | The Item Number will display. This field is not editable.

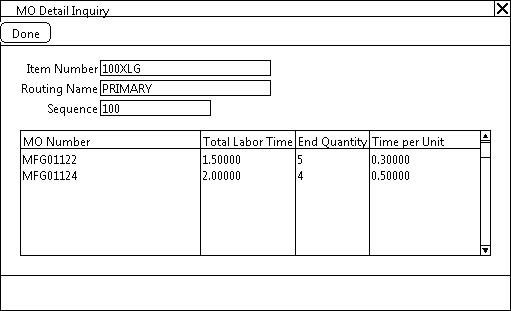

This field is a hyperlink. Clicking on the Item Number will open the MO Detail Inquiry window. Them MO Detail Inquiry window is described in detail in the next section of this document. |

| Routing Name | The Routing name will display. This field is not editable. |

| Sequence | The Sequence Number will display. This field is not editable. |

| Work Center ID | The current Work Center ID entered on the Item Number/Routing Name/Sequence combination will display. The user may enter or select a different Work Center ID from the lookup. |

| # of MO’s | The Number of MO’s that have had Labor Time captured for this Item Number/Routing Name/

Sequence for the last 12 months will display. This field is not editable. |

| Average Labor Time | The Average Labor Time will display. This is a weighted average. The enhancement will calculate Average Labor Time using the following methodology: |

| MO Number | Item Number | Routing Name | Sequence | Total Labor Time per MO | Total MO Receipt Qty | Time per Unit |

| MFG01122 | 100XLG | PRIMARY | 100 | 1.5000 | 5 | 0.30000 |

| MFG01124 | 100XLG | PRIMARY | 100 | 2.0000 | 4 | 0.50000 |

- Sum the Total Labor Time per MO to calculate the Total Labor Time for the Routing Sequence.

(1.5000 + 2.00000) = 3.50000

- Sum the Total MO Receipt Qty for all MO’s with entered Labor Time.

(5 + 4) = 9

- Divide the Total Labor Time by the Total End Quantity to calculate the Average Labor Time.

(3.50000) / 9 = 0.38889

| Average Labor Time, continued | This field is editable. The user may enter a new Average Labor Time to use in the Update Process. |

| Current Labor Time | The current Labor Time entered on the Item Number/Routing Name/Sequence combination will display. This field is not editable. |

| Delta % | The Delta will be displayed as a percentage. The Delta is calculated as:

(Average Labor Time – Current Labor Time/ Current Labor time |

Audit Trail

An Audit Trail SQL table will be provided to capture the following detail of each Update:

- Item Number

- Routing Name

- Sequence

- Labor Time Before

- Labor Time After

- Work Center Before

- Work Center After

- Change Date

- User ID

PLEASE NOTE:

Acme only enters WIP Entry transactions for Labor Time. Setup Time, Machine Time, and Indirect Labor

time are NOT captured in Dynamics GP.

MO Detail Inquiry

Navigation: Utilities-Manufacturing-Update Routing Sequence Utility-Select a Record in the scrolling window-Item Number Hyperlink

This window is used to view the MO Detail that used to calculate the Average Labor Time in the Update Routing Sequence Utility scrolling window.

| Field | Function |

| Done Button | The user will click the DONE button to exit the window. |

| Item Number | The selected Item Number will display. This field is not editable. |

| Routing Name | The Routing Name display. This field is not editable. |

| Sequence | The Sequence will display. This field is not editable. |

| MO Number | The MO Number will display. This field is not editable. |

| Total Labor Time | The Total Labor Time will display. This field is not editable. |

| End Quantity | The MO End Quantity will display. This field is not editable. |

| Time per Unit | The Time per Unit will display. This field is not editable. Time per Unit is calculated as:

(Total Labor Time)/End Quantity = Time per Unit. |

Assumptions/Requirements:

Unless otherwise noted in this document, reporting is not included in this estimate.

Outside Processing Work Centers are NOT used within the Manufacturing Module.

If you are interested in this or any WilloWare design spec, please contact us at this link: