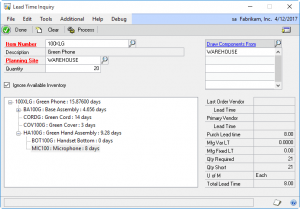

Lead Time Inquiry calculates the minimum time needed to produce a specified quantity of a made item considering manufacturing and vendor lead times and inventory shortages. It calculates a “mini-MRP” on the entire exploded Bill of Materials to arrive at an accurate assessment of how long it will take to make the top-level finished good given the time required to make sub-assemblies and purchase raw materials.

The lead time calculation can be performed either including, or ignoring, available inventory. If you include available inventory, LTI tracks the total requirement of each item as it works its way up from the lowest level of the BOM to the top, and subtracts that from Available Inventory for each part.

For example, if a screw is needed at multiple levels in the BOM, LTI subtracts from the Available Inventory the required quantity needed at the lowest level. If there is a shortage at that point, it calculates how long it will take to order the screw.

However, if there is enough inventory, it moves up to the next level. Perhaps the screw is also needed at this level, and since we already used some screws at the lower level, there would now be a shortage. Purchasing the screw for use at this level may, or may not, affect the overall lead time. If it takes 10-days to make the lower level sub-assembly, but only 3 days to receive a Purchase Order for screws, the shortage does not affect the lead time for the top-level item.

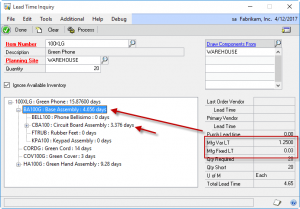

At any level, the lead time to make a sub-assembly is the time required to make the item, plus the longest lead time for its components. As shown above, the lead time to make BA100G is 4.656 days. The total lead time is:

3.376 days to make CBA100

1.25 days of Manufacturing Variable Lead Time (BA100G)

0.03 days of Manufacturing Fixed Lead Time (BA100G)

Other components, such as FTRUB have zeros days lead time because there is not a shortage of those items (or no Lead Time is specified).

Lead Time can also be calculated without considering available inventory, which results in a calculation of the maximum finished good lead time that would be needed to order all raw materials and build all sub-assemblies.