Batch Processing adds the ability to record routing steps based on batch size or processing capacity of a machine. A process which can handle a certain quantity, such as an oven being able to handle 200 bricks per cycle, can now be recorded and correctly scheduled in GP.

Without Batch Processing, routings must be set up based on a “full cycle”. For example, if the oven can handle 200 bricks, and a brick needs to be dried for 10 hours, this would be recorded as 0.05 hours of machine time. When exactly 200 bricks are made, this results in the correct machine time calculation of 10 hours. However, if the batch size is not always the same, this calculation does not result in the correct machine time—for 1 brick or 200 bricks you still need 10 hours.

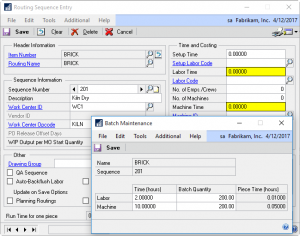

Batch Processing supports recording batch time/capacity for both labor and machine. Since GP Manufacturing ‘thinks’ in terms of per-piece labor and machine time, when an MO is scheduled the Batch Processing enhancement recalculates the per-piece time based on the quantity being made and the capacity per cycle for the labor and machine. So if the Batch Time is 10 hrs in the Kiln for each batch of 200 bricks, and you make 500 bricks, that is a total of three batches (one is partial) for 30 hrs of Kiln time. That works out to a per-piece time of 0.06 so that 500 x 0.06 causes GP to schedule 30 hrs in the Kiln.