LeanMFG is a complete manufacturing suite for Dynamics GP specifically designed for smaller manufacturers, and those whose processes include disassembly, batch, and multi-product production. Targeted for the Business Essentials customer, LeanMFG provides flexibility and ease-of-use that appeals to all users. It does not require Dynamics GP Manufacturing, and can be used alongside it to provide disassembly.

Lean MFG includes:

- Bill of Materials

The Bill of Materials supports Regular, Phantom, Reverse, Disassembly, Batch and Multi-Product bills of material. The BOM was designed to comply with the guidelines of the National Electronics Manufacturing Initiative (NEMI) Perfect BOM Team - Manufacturing Order

supports easy, on-the-fly changes to consumed materials

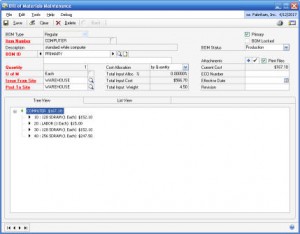

Bill of Materials Maintenance

The LeanMFG BOM supports a multi-level standard and phantom bill. Additionally, the Reverse and Disassembly Bills allow deconstructing a starting material into its component parts.

The Batch Bill, shown above, allows creating a formula bill where the component quantities are calculated in relationship to a specified Batch Quantity.

The Multi-Product bill supports multiple inputs and outputs on a single work order.

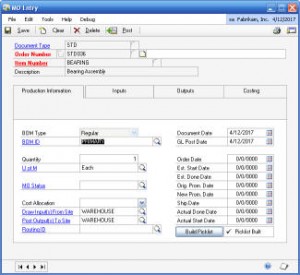

Manufacturing Order Entry

The MO Entry window clearly displays inputs and outputs, and allows the user to quickly add additional materials as needed.Create new manufacturing orders based on existing BOMs, or create a Manual MO by adding items on-the-fly. Create regular assembly orders, or disassembly, multi-product, or reverse orders.

LeanMFG vs Inventory BOM vs GP Manufacturing:

One thought on “LeanMFG”

Comments are closed.