Item Copy

HelpID: 497022112, 497022095, 497022012

Item Copy dramatically reduces the time it takes to create new inventory items and ensures that the many aspects of inventory setup get completed in one quick step. Item Copy creates a new Item by copying setup information from a source item. The utility copies all core Inventory information as well as Manufacturing information, and Field Service Item Extension data.

Item Copy also provides two methods for mass import/update of Items. With the Excel and Table Import utilities a large number of new Items can be created at once, or as part of a regular integration to an external system. The Import Utilities also provide an option to update existing records.

Setup

Navigation: Tools >> Setup >> Manufacturing >> MFG PowerPack Setup

Mark the box next to “Item Copy*”.

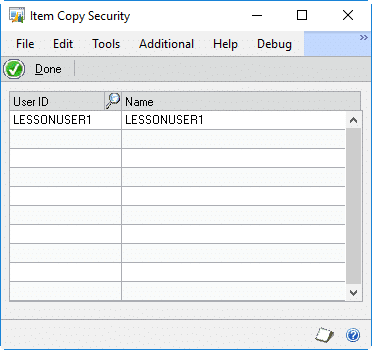

This feature has additional setup. Double-click on “Item Copy*” to open the Item Copy Security window. After completing the Item Copy Security setup, all users must re-start GP to activate this feature.

Item Copy Security is OPTIONAL. If security is NOT set, all users will be able to make changes to the options controlling what information is copied.

If one or more User IDs are entered into the Security window, the Options list in the Item Copy window will be editable by those users, but view-only for all other users. If no User IDs are entered in the Security window, all users will be able to make changes to the Item Copy settings. Using security allows you to provide access to Item Copy to more users while ensuring they cannot make changes to the copy options.

Options

Navigation: Tools >> Utilities >> Inventory >> Item Copy. Item Copy is also available from the Additional Menu on Item Maintenance (Additional >> WW Item Copy), and by clicking the COPY button on Item Maintenance.

NOTE: If you accidentally turned off the Item Maintenance Copy Button navigation to Item Copy, open the Item Copy window from the Additional Menu, then click GoTo >> Clear My Item Maintenance-Item Copy Setting.

Item Copy will copy all the selected setup from the Source Item Number to a new Destination Item Number.

Specific options can be turned on or off by marking/unmarking the checkboxes. For example, if the Bill of Materials will be entered manually after the new Item is created, unmark “Manufacturing Bill of Materials”.

Item Copy will remember the settings the next time the window is opened.

The setup information for the Source Item Number can be viewed by double-clicking on any of the setup options. For example, double-clicking on “Item Maintenance” opens the Source Item Number in the Item Maintenance window.

The nodes with plus signs have additional options.

For all Item-related records that have a Record-level Note, Item Copy provides the option to create the new Item Number with a blank note (the default setting), or to copy the note from the Source Item.

To change the Note Option, click on the Note Icon. The image below shows how the note icon changes when the “Copy Note” option is set.

![]()

Click on the note icon to change the setting

![]()

The Manufacturing standard costing information is copied automatically when the Item Master record is copied. The Zero Standard Costs option will clear (set to zero) all costing fields in the new item. A standard cost rollup should be done on the new item to calculate the standard cost information.

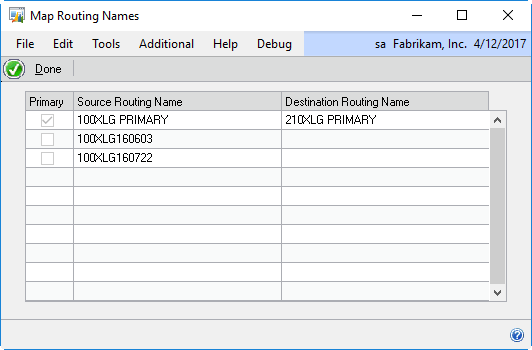

When copying a made item, all Routings can be copied from the Source Item, but the Primary Routing is required. After selecting the Source Item Number, click the Go To button and select Map Routing Names.

The Primary Routing must be mapped if (1) Copy BOM-Routing Links is marked and/or (2) Copy Routings is marked.

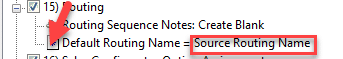

Enter a Destination Routing Name for each Routing you want to copy to the new item. See the ROUTING option in the Item Copy window for a setting to control the Default Routing Name. The default can be either the Destination Item Number or the Source Item’s Routing Name.

NOTE: when using Excel or Table import the Primary Routing is automatically mapped. The Destination Routing Name will be set based on the DEFAULT ROUTING NAME option in setup. The Default Routing Name setting is also used to populate the Map Routing Names window with a default value (i.e. the Default Routing Name setting is used if a manual mapping is not entered).

Double-click on the icon to switch the source used for the Routing Name.

Custom Logic

Item Copy adds a SQL Stored Procedure to the company database called wspItemCopyPost. It can be edited to add additional processing to the Item Copy routine that runs after all of the other Item Copy steps have executed.

The empty stored procedure looks like this:

Edit the stored procedure to add any custom post-copy updates that you need to run. For example, the script below has been changed so it updates the Item User Defined Field #1 with “COPIED”.

Manual Item Copy

Source: Select Source = Manual

Source Item Number: Enter the Source Item Number or select one from the Lookup.

There are two approaches to choosing a Source Item Number. One option is to use an Item that is something your normally purchase or make. A “normal” Item Number. Another option is to create special “template” Items that are used only as Source Items for Item Copy. With this approach, you can think of the Template Items as a sort of Item Class–you would create a Template Item that has the generic settings needed by a class of Items.

When creating Template Items, keep in mind that there are several settings that cannot be changed after an Item is created, such as Item Type, Valuation Method, Quantity Decimals, and Currency Decimals. U of M Schedule can sometimes be changed, but when planning for Template Items treat this field as fixed. At a minimum, one Template Item would be required for each variation your inventory will have of Item Type, Valuation Method, Quantity Decimals, and so on.

Destination Item Number: The Destination Item Number is the “new” Item. It cannot exist in GP.

If you also purchased WilloWare’s SmartParts module, the blue expansion arrow will be enabled and provides access to the SmartParts ID Generator window.

Copy: Click the COPY button to create the new item.

The Item Copy process creates a new Item by copying the following data (depending on the marked options):

- Item Maintenance & Note. It copies the Item Master, and if the Source Item is Serial Numbered or Lot Numbered, it will also copy the Serial/Lot Number Mask.

- Item Currencies

- Item Price List, and Price List Options

- Item Quantities includes Item-Site Assignment and Item Resource Planning

- Item Site Default Bin Quantities

- Item Purchasing Options

- Manufacturer’s Item Numbers

- Item-Vendor Assignment

- Kits

- Fulfillment Detail

- Item Engineering & Note

- Alternate Items

- Inventory BOM & Note. Includes options for Active, Pending, and Obsolete BOMs.

- Manufacturing BOM & Note. Includes options for MFG, ENG, ARCH, CONFIG and SUPER BOMs.

- Routing & Sequence Notes. Includes the ability to copy the Primary Routing, and any number of alternate routings through Routing Name Mapping.

- Sales Configurator Item Option Assignments

- QA Item Procedure Setup & Note

- Field Service Item Extension

- Batch Processing (MFG PowerPack)

Excel Import

Item Copy can be used to create a large number of new Items by importing data from an Excel spreadsheet. It can also update existing items.

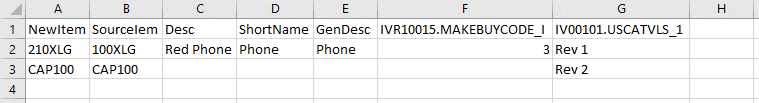

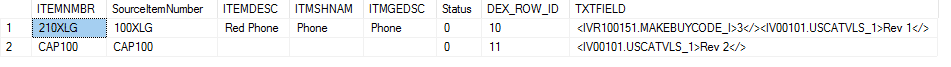

The spreadsheet must have Columns A-E as shown below.

Columns A-E are required and must be in the order shown.

Columns beyond E are used to update specific fields.

The example above shows both an “Add New” record (row 2) and an “Update” record (row 3).

Add New & Update Existing

When importing from Excel, mark one or both checkboxes (Add New, Update Existing).

Both can be marked at the same time.

Mark only one to prevent the import from accidentally Updating, or accidentally Adding New.

If Description, Short Name, or Generic Description are not provided for a NEW Item, they will be copied from the Source Item.

The Import can also update specific fields on existing records. When creating a new Item, first the new Item will be created, and then the updates will run. To update fields, the Column Header in the spreadsheet must contain the Table & Field Name.

For example:

IVR10015.MAKEBUYCODE_I

IV00101.USCATVLS_1

The column header must contain: Table.FieldName

The rows below the column header should contain the value you want to set in the specified field. As shown above, the Item Master User Defined Field #1 will be set to “Rev 1” for 210XLG (a new Item), and “Rev 2” for CAP100 (an existing Item).

If a field is blank, no update will be performed. This means that the spreadsheet can have multiple update columns which are NOT used for every item. It also means that it is not possible to set a field to empty/blank because an empty field will prevent any update from occurring.

Note that for existing Item updates, both the New Item and Source Item columns MUST contain the Item Number to be updated.

The table to be updated must contain an ITEMNMBR column. Also, if the table has many records for an item (such as the Item Quantity Master, IV00102), there is no way to update a single Item-Site record using Item Copy. An update to IV00102 will update ALL site records for the specified Item.

Excel Import reads the Excel spreadsheet and populates the Item Copy staging table, and then executes the Table Import routine. See the Table Import section for more details.

CAUTION! The updates are performed exactly as provided. No data validation is performed by ItemCopy. It is critical to test imports against sample data before running in a live environment. Also consider that the update will be performed in the following manner:

update Table

set FieldName = Value

where ITEMNMBR = NewItem

Table Import

Item Copy can be used to create a large number of new Items by importing data from a SQL staging table. It can also update existing items from the same table.

The staging table is in the company database: W4970ItemCopy

ITEMNMBR is the “new item” and is also the key on the table.

After importing is complete, ItemCopy will clear the table so new records can be added.

The example above shows both an “Add New” record (row 1) and an “Update” record (row 2).

When importing from Table, mark one or both checkboxes (Add New, Update Existing). Both can be marked at the same time.

Mark only one to prevent the import from accidentally Updating, or accidentally Adding New.

If Description, Short Name, or Generic Description are not provided when creating a new Item, they will be copied from the Source Item.

The Import can also update specific fields on existing records. When creating a new Item, first the new Item will be created, and then the updates will run. To update fields, populate the TXTFIELD with the Table, Field and Value to be updated. The data must be in the following format:

<Table.Field>NewValue</>

For example:

<IVR10015.MAKEBUYCODE_I>3</>

<IV00101.USCATVLS_1>Rev 2</>

The “new value” cannot be blank. If a field is blank, no update will be performed.

Note that for existing Item updates, both the ITEMNMBR and Source Item Number columns MUST contain the Item Number to be updated.

CAUTION! The updates are performed exactly as provided. No data validation is performed by ItemCopy. It is critical to test imports against sample data before running in a live environment. Also consider that the update will be performed in the following manner:

update Table

set FieldName = Value

where ITEMNMBR = NewItem

The table to be updated must contain an ITEMNMBR column. Also, if the table has many records for an item (such as the Item Quantity Master, IV00102), there is no way to update a single Item-Site record using Item Copy. An update to IV00102 will update ALL site records for the specified Item.

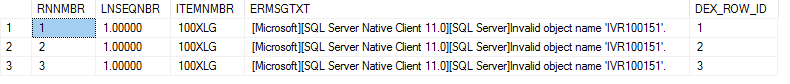

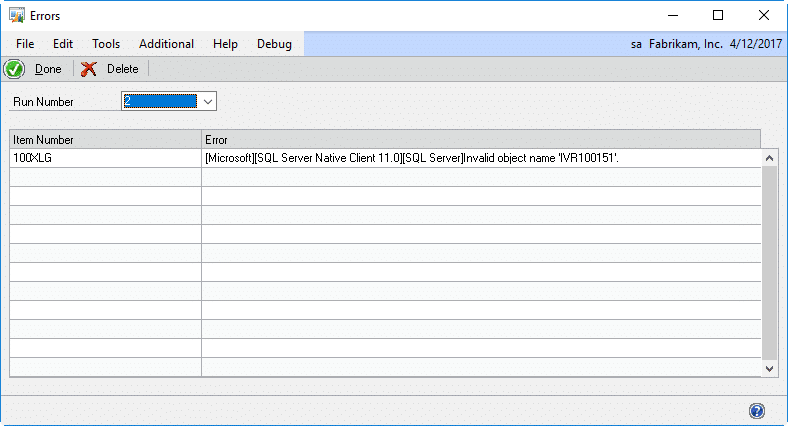

Import Errors

Navigation: from the Item Copy window click GoTo >> Import Errors

All errors are reported in a Company Database SQL table: W4970ItemCopyErr.

RNNMBR (Run Number) increments by 1 each time Excel or Table import runs.

The error list can also be viewed from inside GP. On the Item Copy window, click the GoTo button, then select Import Errors. DELETE clears all errors from the table for the selected Run Number.

Item Copy Tables

| Physical Name | Descriptive Name | Technical Name |

| BM00101 | Bill of Materials Header | bmBill |

| BM00111 | Bill of Materials Component | bmBillComp |

| BM010115 | MFG Bill of Material Line File | MFG BOM_Line |

| BM010415 | MFG BOM Revision | MFG BOM_Revision |

| BM010200 | MFG BOM-Routing Link | MFG BOM_Routing |

| CT00003 | MFG IC Cost Standard Item Class Default | MFG IC_COST_IV_STD_Item_Class_SETP |

| CT00102 | MFG IC Cost Item Master | MFG IC_COST_IV_Item_MSTR |

| ICIV0323 | MFG IC_IV_STANDARD | MFG IC_IV_STANDARD |

| IV00101 | Item Master | IV_Item_MSTR |

| IV00102 | Item Quantity Master | IV_Item_MSTR_QTYS |

| IV00103 | Item Vendor Master | IV_Item_MSTR_VNDR |

| IV00104 | Item Kit Master | IV_Item_MSTR_KIT |

| IV00105 | Item Currency Master | ivItemCurr |

| IV00106 | Item Purchasing | ivItemPurch |

| IV00107 | Item Price List Options | ivItemPriceListOpt |

| IV00108 | Item Price List | ivItemPriceList |

| IV00109 | Item Serial Number Mask | IV_SerialNumberMask |

| IV00112 | Item Site Bin Master | ivItemSiteBinMstr |

| IV00115 | Multiple Manufacture Items Master | IV_MFG_ITM_MSTR |

| IV00117 | Item Site Bin Priorities | ivItemSiteBinPriority |

| IV10400 | Extended Pricing Price Group Work | ivExtPricingGroupWork |

| IV10401 | Extended Pricing Price Sheet Work | ivExtPricingPriceSheetWork |

| IV10402 | Extended Pricing Price Sheet UofM Work | ivExtPricingPriceSheetUofMWork |

| IV10403 | Extended Pricing Promotion Free Item | ivExtPricingPromoFreeItem |

| IS090000 | MFG Manufacturing Fulfillment Item Master | MFG IC_SOP_Fulfillment_Item_MSTR |

| IVR10015 | MFG Item Engineering File | MFG IV_Item_ENG |

| IVR10100 | MFG Alternate Parts | MFG IV_Alternates |

| IVR50000 | MFG Inventory Item Options | MFG IV_Item_Options |

| MN010000 | MFG Notes | MFG_Notes |

| MP030000 | MRP Exclusion List | MRP_Exclude |

| QA160032 | MFG QA_Item_Procedure | MFG QA_Item_Procedure |

| RT010001 | MFG routing_mstr | MFG routing_mstr |

| RT010130 | MFG routing_line | MFG routing_line |

| SVC00951 | Item Master Extensions | SVC_Item_MSTR_Ext |

| SY03900 | Record Notes Master | SY_Record_Notes_MSTR |

| TARD1001 | MFG TA_Reference_Designator_Line | MFG TA_Reference_Designator_Line |

| W4970BatchPlanRouting | wBatchPlanRouting | WBatchPlanRouting |

| W4970ScrapAccts | wScrapAccts | wScrapAccts |