PO Generator Integration

PO Generator Integration provides a method to add additional sources of supply and demand into the POGen calculations. There may be transactions in Dynamics GP, such as unallocated Picklists on Open Manufacturing Orders, that will require inventory but they are not seen by POGen.

PO Generator Integration would not be used in an environment where MRP is in use.

PO Generator Integration makes use of a field in the Item Master Quantities table called QTY Requisitioned. This field is not normally used by Dynamics GP but it is included in the POGen calculations. If you have a module that is using QTY Requisitioned, do not enable PO Generator Integration.

Setup

Navigation: Tools >> Setup >> Manufacturing >> MFG PowerPack Setup

Mark the box next to “TWK: PO Generator Integration”.

Click DONE on the MFG PowerPack Setup window. This Tweak will be active immediately for the current user. Other users will need to close GP, then log-in again to activate it.

SQL Scripting is required to use PO Generator Integration. The MFG PowerPack installation routine creates a stored procedure called wspPOGen. PO Generator Integration will have no effect on the POGen calculations until the wspPOGen stored procedure has been edited to populate the QTYRQSTN field in IV00102.

The POGen calculation calculates the Quantity Available as:

QTY On Hand +

QTY On Order –

(QTY Allocated if Include Allocations is marked) –

(QTY Requisitioned if Include Requisitions is marked) –

(QTY Backordered if Include Backorders is marked)

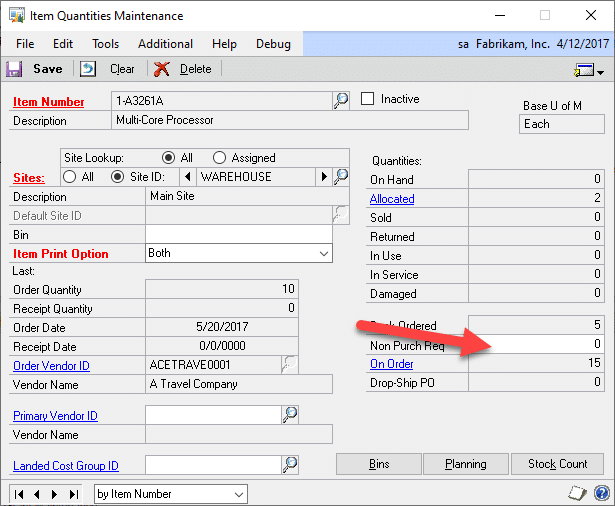

QTY Requisitioned is not normally used by GP as it is a manually entered value on the Item Quantities Maintenance window at the Item-Site level.

PO Generator Integration will calculate a value for “Non Purch Req” (QTY Requisitioned). QTY Requisitioned is a “demand” value, so a positive value in the field is SUBTRACTED from QTY Available. You can use QTY Requisitioned to include supply by making it a negative value—subtracting a negative value will ADD to QTY Available.

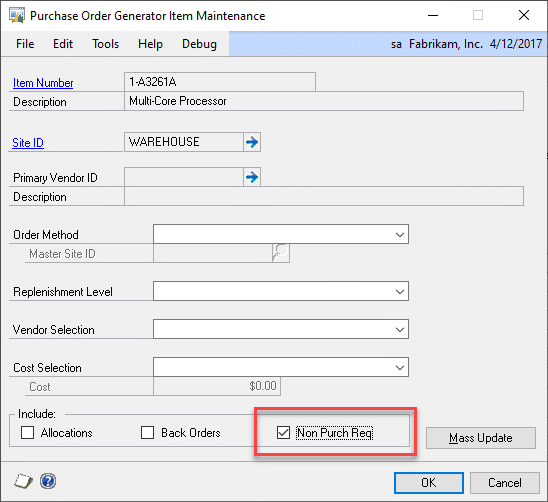

The INCLUDE NON PURCH REQ checkbox must be marked on POGen Item Maintenance.

Below is an example of how to edit the wspPOGen stored procedure. In this example it is calculating the total inventory requirement from Manufacturing Picklists where MO Status is OPEN.

create proc wspPOGen

@FromItem varchar(100),

@ToItem varchar(100),

@FromSite varchar(100),

@ToSite varchar(100),

@FromBuyer varchar(100),

@ToBuyer varchar(100),

@FromVendor varchar(100),

@ToVendor varchar(100),

@FromItemClass varchar(100),

@ToItemClass varchar(100)

AS

;with ttls as

(select ITEMNMBR, LOCNCODE, sum(MRPAMOUNT_I) TTL from PK010033

where MANUFACTUREORDERST_I = 2

group by ITEMNMBR, LOCNCODE)

update a

set QTYRQSTN = TTL

from IV00102 a join

ttls b on

a.ITEMNMBR = b.ITEMNMBR and

a.LOCNCODE = b.LOCNCODE

where a.ITEMNMBR >= @FromItem

and a.ITEMNMBR <= @ToItem

The stored procedure is initially empty and does nothing when POGen runs.

The QTYRQSTN field can be negative or positive. If you have SUPPLY transactions that are not visible to POGen, such as from an external manufacturing system, add those as a NEGATIVE amount (they will decrease the total requirement calculated by POGen). If you have DEMAND transactions that are not visible to POGen, such as the raw materials needed by an external manufacturing system, add those as a POSITIVE amount (they will increase the total requirement calculated by POGen).