MOP-SOP Linking

MORI will also check if an MO is linked to a Sales Transaction. If it is, the Sales Transaction will be updated (by moving Quantity Backordered to Quantity To Invoice), and the inventory will be allocated.

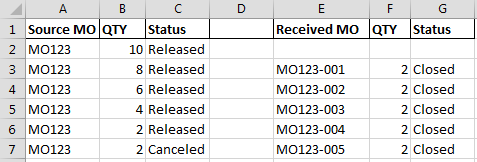

The example below shows how MORI will process multiple receipts against an MO.

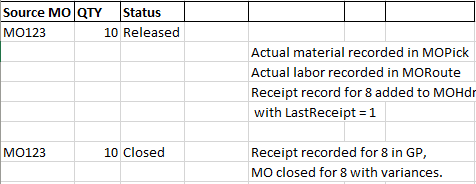

In this example, the source MO (MO123) is created inside GP for a quantity of 10. After each partial receipt is created, the source MO is adjusted downwards by the receipt quantity, the Picklist is rebuilt and the routing is rescheduled. The rebuild and reschedule process causes MRP and CRP to see the correct remaining demand (i.e. components are no longer needed to produce 10 after the first receipt, since only 8 remain to be built). Setting the LastReceipt flag is not necessary because the final receipt brings the Quantity on the Source MO down to zero. The final receipt could also be for 3 or more, and the Source MO will still be canceled for whatever quantity it had left.

Each split MO is created using the same BOM, Routing, and Scheduling Preference as the source MO.

When a receipt is posted which would bring the End Quantity of the Source MO to zero, or below zero, MORI will automatically Cancel the Source MO.

In the scenario above you may also be recording actual material or labor consumption, if it is known at each step in the process.

NOTE: When MORI creates partial receipts for MO123 (as shown above), you will create records in the MORI table using the source MO Number (i.e. MO123) and increment the SEQUENCE1 column for each additional receipt. When MORI detects a partial receipt, or that the MO already has one or more partial receipts, it will locate the next Split MO Number and update the MORI tables to use that number. As shown above, MO123 was the value inserted into the MORI tables by the external integration. When MORI detected a partial receipt, it updated the Manufacture Order Number in the MORI table to be MO123-001. When a second receipt was created for MO123 was created, MORI renumbered it to MO123-002. Your integration will always use the Source MO (i.e. MO123), but after processing by MORI the staging tables will show a different MO Number (such as MO123-001).

If actual material and/or labor consumption is not known until production is complete, and backflushing is not used, and you will close the MO short of the End Quantity, you should track all production in the external system and only integrate one single receipt.

In this scenario all of the production is recorded in an external system, and only integrated when production is complete and all information is known about the process (i.e. actual material/labor are known). That information is fed into the MORI tables. When MORI creates an MO Receipt it will also close the MO. If you are backflushing components and/or labor, the MO Close will consume using the “Start Quantity” option in the MO Close.