CompleteCount provides the tools needed to perform a controlled cycle count in Dynamics GP using stock tags. The stock tag method of conducting a physical count provides for an auditable record of the count, ensures a higher degree of accuracy, and keeps to a minimum the downtime required to conduct the count.

The first step in performing a Cycle Count is often creating smaller groups of items so they can be counted more quickly on a regular basis. Usually that is done through assigning ABC Codes based on inventory value.

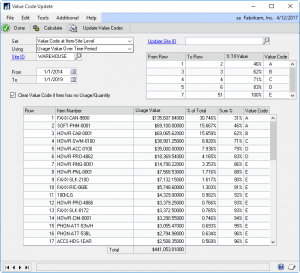

CompleteCount expands the typical “ABC Code” assignment logic by providing the ability to assign “Value Codes” of A thru Z.

By default the Value Code Assignment utility attempts to group items so that the those comprising the top 70% of value are assigned A. The next 20% are B, and the remaining large quantity of low value items are assigned C. In an environment with a lot of inventory, using only ABC still results in groups that are too large to count quickly. To address this, the Value Code Assignment window can create up to 26 subdivisions (A to Z). The Value Codes are tracked at the Item-Site level so that planning cycle counts can occur separately at each warehouse.

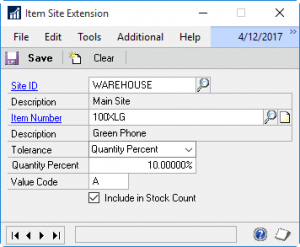

CompleteCount can also track an allowable count variance (or Tolerance) for each Item within a Site.

The Count Tolerance value is checked before the final count can be submitted. If one or more items have a count, for example that is greater than 10% above or below the expected quantity, they are flagged. A manager needs to either approve the count as-is (i.e. certify that the out-of-tolerance count for an item is actually correct), or move those items off the current Stock Count to a new Stock Count so they can be re-counted.

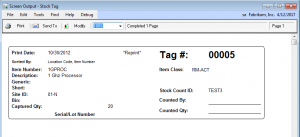

Once items have been assigned to a cycle count you can start printing tags and attaching them to physical locations throughout the warehouse. The tag will be used later by employees performing the count to record the inventory located in the vicinity of the tag. Being able to print and distribute tags ahead of time allows you to prepare for the count without having to freeze inventory.

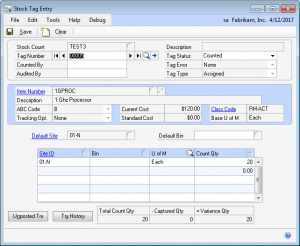

When you are ready to perform the physical count, the cycle count is “Started” in the Dynamics GP Cycle Count module. This creates a snapshot of the current On Hand quantities for the items on the count. This quantity is referred to as the Captured Quantity.

As inventory is counted and recorded on the tags, the tags are entered into the CompleteCount Tag Entry window. To speed data entry the Stock Count Entry window allows an unlimited number of users to enter tags for the same Stock Count. The system will automatically tally the total count for an item if it has quantities recorded on several different tags.

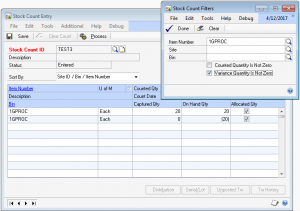

CompleteCount adds Stock Count Filters to the Stock Count Schedule and Stock Count Entry windows, which provide the ability to quickly locate specific Items in the count with a number of restriction/search criteria.

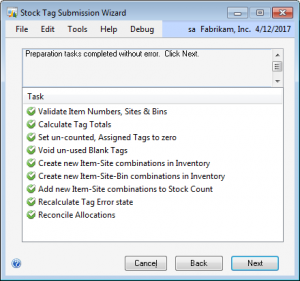

All tags that were printed must be accounted for before the count totals can be submitted. When the tags are submitted, the total count quantities will appear in the Dynamics GP Stock Count module. When the Dynamics GP Stock Count module processes the final count it creates the needed inventory transactions.

ExcelLink provides another level of cycle counting support. ExcelLink exports the stock count to Excel. Users can enter count information in multiple copies of the spreadsheet. When the spreadsheets are imported, CompleteCount adds them together to arrive at a total count, which is then used to update the GP Stock Count.