MFG Import for Dynamics GP Manufacturing contains two utilities:

- Bill of Materials Import

- Routing Import

Both utilities are designed to make it easy to perform regular imports and updates to Bills of Material and Routings from an external file (Excel).

BOM Import

The Import Mapping utility allows mapping all of the Bill of Materials fields to fields in a source file, or predefined Constants, or system provided Defaults. During the import existing BOMs can either be revisioned (which makes a copy of the existing BOM and moves it into BOM History tables), or replaced by the imported BOM.

BOMImport can also create new Item Numbers on-the-fly through the use of Template Items and an integration to WilloWare’s Item Copy in MFG PowerPack (Item Copy must be licensed separately). As new items are imported, all of the setup needed to create the new item is copied from the Template Item.

Multiple levels of a BOM can be imported at the same time, as well as multiple BOMs for different items.

BOMImport can also create a simple routing by copying a routing from a “template” item. Since GP Manufacturing requires a Routing for all Make items, copying from a Template Item is an easy way to get a “simple” routing created in GP for new items.

Routing Import

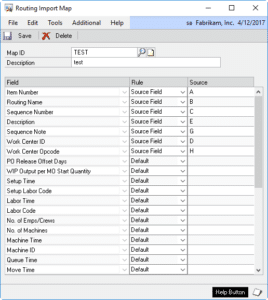

Create or update full GP Manufacturing Routings in Dynamics GP with our Routing Import. The Routing Import Map provides an easy way to map columns from a source Excel file to fields in the Routing. The utility will provide default values for most fields.

Routing Import can import text from Excel to create Routing Sequence Notes.

It also supports using Routing OpCodes. With an OpCode, Routing Import can populate almost every field on a Routing Sequence by pulling setup from the OpCode. Simply provide an OpCode in the import file, and Routing Import can populate Labor Codes, Machine Codes, Setup Time, Run Time, and all of the other key Routing Sequence fields.