Customization DS0803

Auto-create PO from MO Pick List

Problem Definition:

ACME requires the ability to auto-generate Purchase Orders direct from Manufacturing Order Pick Lists for Buy Items with shortages that are not MRP planned for the Item/Site combination.

Purchase Order Lines should be consolidated if multiple lines share the same Vendor ID.

Design Features:

Navigation: Transactions >> Manufacturing Orders >> Pick List >>Additional >>PO Generator

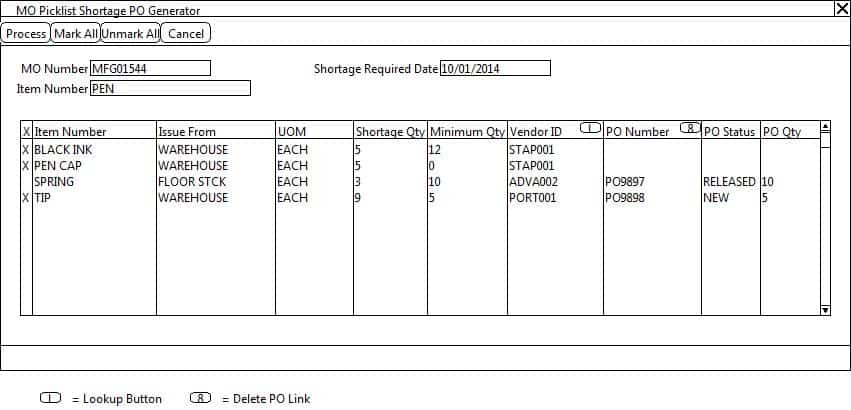

From the Manufacturing Order Pick List, the user will navigate to Additional >>PO Generator. The MO Picklist Shortage PO Generator window will open if the MO Status is set to Released, Partially Received, Hold, Complete or Closed. The window will be view only if the MO Status is set to Hold, Complete, or Closed.

This window is used to create Purchase Orders for the MO Picklist shortages as well as to view previously created Purchase Orders.

Please Note: Unless otherwise noted, all fields below are not editable.

|

Field |

Function |

|

Process |

The user will click the PROCESS button to generate or update Purchase Orders for all marked Item Numbers. Please see the section below entitled PROCESS BUTTON for more details. |

|

Mark All |

The use will click the MARK ALL button to mark all eligible Item Numbers in the scrolling window. An Item Number is considered eligible if:

|

|

Unmark All |

The user will click the UNMARK ALL button to unmark all Item Numbers in the scrolling window. |

|

X |

This field is a checkbox. The user will check the checkbox to mark an Item Number to be included in the PO Creation Process. An Item Number can only be marked if:

|

|

Item Number |

All Item Numbers on the MO Picklist matching the following criteria will display:

|

|

Issue From |

The Item Number’s Issue From Site ID from the MO Picklist will display. |

|

UOM |

The UOM from the MO Picklist for the Item Number will display. |

|

Shortage Qty |

The Shortage Qty will be set equal to the Item’s Picklist Required Qty. |

|

Minimum Qty |

The Minimum Qty for the Item Number/Site ID combination in the Item Resource Planning Card will display. |

|

Shortage Required Date |

The MO Start Date will display. |

|

Vendor ID |

The Last Order Vendor ID will default. The user may enter or select a Vendor ID from the lookup should a Last Order Vendor ID not exist or if they wish to change the Vendor ID. The user may NOT update the Vendor ID, if a Purchase Order is already linked to the Item Number. Please Note: The Vendor ID lookup will only display Vendor ID’s that are assigned to the Item Number. |

|

PO Number |

If a Purchase Order Number is already linked to the Item Number, the PO Number will display. Please Note: To delete a PO Link from a Picklist Line Item, select the Line Item and then click on the Link Button. The user will be prompted, “Do you want to break the link to PO XXXX?” If the user clicks NO, the enhancement will do nothing. If the user clicks YES, the enhancement will break the link. The Purchase Order itself will NOT be changed. Only the link to the MO Picklist will be removed. |

|

PO Status |

The linked Purchase Order Number’s status will display. |

|

PO Qty |

The linked Purchase Order Number’s Quantity Ordered will display. |

PROCESS BUTTON

When the user clicks the PROCESS BUTTON the enhancement will do the following for all Item Numbers that do NOT already have a linked PO Number:

- Group the Item Numbers by Vendor ID.

- Generate one Purchase Order Number be Vendor ID.

- The PO Header will contain the following detail:

- PO Type: Standard

- PO Number: Next chronological PO Number

- Vendor ID: Vendor ID from scrolling window

- PO Date: User Date

- Currency ID: Company’s Functional Currency

- Purchase Address ID: Vendor ID’s default Bill To Address

- Bill To Address ID: Vendor ID’s default Bill To Address

- Ship To Address ID: Company’s Primary Address ID

- Ship Method: Vendor ID’s default Shipping Method

- Contract Number: MO Number

- Payment Terms: Vendor ID’s default Payment Terms

- The PO Line(s) will contain the following detail:

- Item Number: Item Number from scrolling window

- U of M: U of M from the scrolling window

- Quantity Ordered: shortage Qty or Minimum Qty from the scrolling window. (The larger of the two Quantities will be used.)

- Unit Cost: Vendor ID’s Last Originating Cost for the Item Number

- Site ID: Issue From Site ID from the scrolling window

- Required Date: MO Start Date

- Line Comment: MO Number

When the user clicks the PROCESS BUTTON the enhancement will do the following for all Item Numbers that do already have a linked PO Number at Status NEW:

- The PO Line’s Quantity Ordered will be updated to the greater of the Shortage Qty or the Minimum Qty from the scrolling window.

- The PO Line’s Site ID will be updated to the MO Picklist’s Issue From Site ID.

- The PO Line’s Required Date will be updated to the MO Pickist’s Required Date for the Item Number.

Please Note:

ACME should NOT delete Item Numbers from the MO Picklist. If an Item Number is NOT required, the Picklist Quantity should be updated to 0.

Assumptions/Requirements:

- Unless otherwise noted in this document, reporting is not included in this estimate.

- Multi-Currency is not utilized in the Purchasing Module.

- ACME does NOT override MO Picklist Shortages during the MO Release process.

- ACME does NOT use the BOM-Routing Link functionality or BOM Lead Time Offset functionality within the Manufacturing module.

For information on this design, or any other WilloWare customization or product, please contact us at:

www.willoware.com/contact-me/