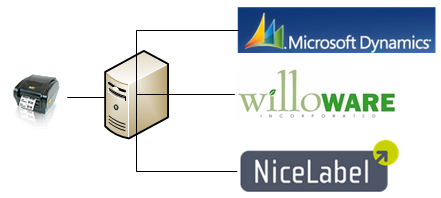

WilloWare’s LabelLink acts as an intermediary between Microsoft Dynamics GP and label printing software. All three pieces of software must be installed on the same computer, along with a barcode label printer.

LabelLink can be used with any labeler software, including:

- Teklynx (Codesoft) (www.teklynx.com)

- WASP Barcode Technologies (Wasp Labeler) (www.waspbarcode.com)

- NiceLabel (www.nicelabel.com)

- Bartender (www.seagullscientific.com)

- Zebra Designer (www.zebra.com)

In addition to LabelLink from WilloWare, you must also purchase:

- Label printing software (such as Teklynx’s Codesoft, Wasp Barcode’s Labeler, or NiceLabel)

- A Barcode Label printer (a roll printer is strongly recommended)

Data flow from Inventory Transfer –> LabelLink –> LabelLink Database Table

LabelLink supports printing barcode labels for inventory items from many places in GP, such as:

- Purchase Orders and Receivings Transactions

- Manufacturing Orders and Receipts

- Item Transactions and Transfers

- SmartList

LabelLink reads the inventory items from the transaction, such as a PO Receipt, then provides several options in LabelLink for how to print the labels. For example, you may choose to generate one label per Base Unit of Measure on the Purchase Order, or change the quantity of labels to print.

The SmartList integration allows printing labels using ANY data from ANY SmartList Favorite.

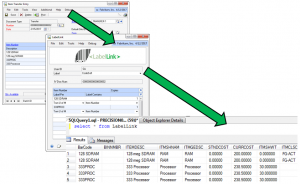

LabelLink collects data from several places in GP to create the labels. If labels are being printed from a PO Receipt, LabelLink will include data from the PO, PO Receipt, PO Receipt Lines, PO Serial Lot table, Item Master, Vendor Master, and so on. One record per label is created and sent to the LabelLink table in the SQL database.

Regardless of the location in GP from which labels are printed, the generated labels are always sent to the same LabelLink table. This greatly simplifies creating the label report, allowing a single report to be created for all labels, regardless of the source data in GP. Without LabelLink a separate label report would be needed for printing from Purchase Orders, PO Receipts, MO Receipts, and so on.

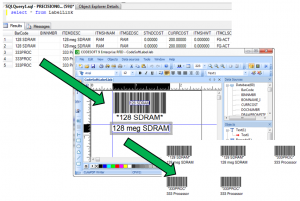

Data flow from the LabelLink Database Table –>

Label Printing Software –> Printed Labels

After sending the generated labels to the LabelLink table, LabelLink launches the labeler software.

The LabelLink table contains a column for User ID (GP User ID). The label report must contain a restriction by User ID. When the labels are printed, the label printing software will only pull records from the LabelLink table that belong to the specified User ID.

Since the label report will have an ODBC connection to a GP Company Database, if you have multiple company databases, a separate label report is required for each User-Company combination. For example, if LESSON– USER1 needs to print labels from both TWO and TEST, you will need two separate label reports. The LabelLink Setup window will map a label report to a user, and automatically select the correct report when the user prints labels.

The label printing software pulls data for the barcode labels from the LabelLink table. Since LabelLink has done the work of collecting all the needed data into one record in one table, no complicated table linking is required when building the label report in the label printing software.

The label printing software packages (i.e. Wasp Labeler, Codesoft, NiceLabel) support all of the most common printers, and can print complex barcode labels with multiple barcodes in different orientations. The label printing software packages are similar to Crystal Reports. They are graphical report design packages that pull data from a database via an ODBC connection. They have special features designed to handle complex graphical layouts for labels.