We just released (3-OCT-2017) a new build of MOGenerator’s MO Receipt Integration (MORI) that now has support for WIP Inventory. This new functionality provides the ability to record usage of raw materials as it happens. There are two components of the new functionality: (1) adjusting Picklists for WIP transfers, and (2) forcing consumption of components from the WIP Site.

WIP Transfers

The process is tailored for an external application integrating into GP, such as a Warehouse Management package, or Shop Floor Control software. We designed this approach in consultation with Without Wire Inventory Sciences.

After creating a Manufacturing Order in GP, the external software retrieves the Picklist from GP and uses it to create one or more Inventory Transfers to move inventory from stock to WIP.

The Inventory Transfer is a “picking transaction” for a Manufacturing Order. The external software tells MORI about the transfer by adding a record to the MOIVTrx table.

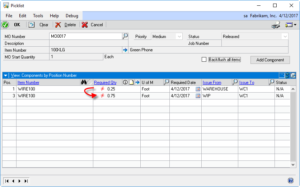

When the MORI processor runs, the first step is now to check the MOIVTrx table for new transfers. As shown above, there are two transfers for MO0017.

It processes transfers IN to the WIP Site first, then transfers OUT of WIP. The items transferred are matched to lines on the MO’s Picklist.

When inventory is transferred into WIP, the original Picklist line is decreased by the transfer quantity. A new Picklist line is added for the same item where the Issue From Site is the WIP Site. An example is shown above.

In the example, 0.75 FEET of WIRE100 have been transferred into WIP from WAREHOUSE. The original Picklist line with Issue From of WAREHOUSE, was decreased from 1.00 to 0.25, and a new Picklist line was added for 0.75 with an Issue From of WIP.

The original line will draw down until it reaches zero, but the WIP line will increase to show the entire quantity transferred into WIP. Likewise, if a transfer is posted OUT of WIP back into WAREHOUSE, the WIP line will be decreased until it reaches zero, and the original line will be increased until it reaches the original quantity.

There are several effects to note about this process.

First, inventory used by manufacturing can be put into WIP at the moment it is picked, and the MO does not need to be Released. This ensures the GP inventory quantities are current and accurate.

Second, by automatically adjusting the Picklist to reflect the transfer, Materials Requirements Planning (MRP) can detect the change in demand (i.e. decreasing need for WIRE100), and still see remaining demand.

Third, the Picklist becomes a live record providing a quick reference to inventory issued to an MO, and the inventory still required.

Lastly, by moving it into a WIP Site, rather than adjusting it out and tracking the dollar value, it is possible to perform a physical inventory on WIP.

WIP Consumption

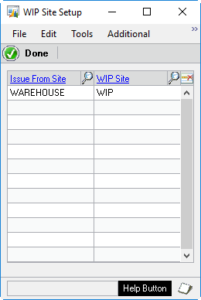

Setup in MOGenerator creates a relationship between a main inventory site and a WIP Site. This is shown below:

When an MO Receipt is processed, MORI creates a “split-MO” off the parent, which it runs through as a QuickMO. When MORI builds the Picklist it forces the Issue From Site to be the WIP Site.

As shown above, if the original MO has a Draw Inventory From of WAREHOUSE, MORI will force the components to be consumed out of WIP.

The MOPick table can still be used to direct MORI to consume specific quantities of specific materials.