If you would like to receive immediate updates regarding product releases, please follow us on Facebook , LinkedIn, or Twitter.

Product Highlights

Product Highlights

You have two boxes of 14-mm nuts. One box has a gold-chrome finish, and the other has a black-chrome finish. Other than the color difference, they are physically identical and can be used interchangeably. The black-chrome item is slightly more expensive, and is required for one of your products, so you do not order it often, and usually end-up having to order more than you need.

Keeping those black-chrome nuts around ties-up capital in inventory, occupies storage space, and incurs a little bit of additional labor expense each time they are cycle counted. If only there way a good way to use them up.

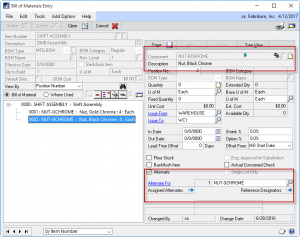

There is! Since they are equivalent to the gold-chrome nuts, they can be added as a BOM Alternate Item to the Dynamics GP Manufacturing Bills of Material which use the gold-chrome nuts. This setup is shown below:

Once the Alternate Item relationship is created, MFG PowerPack’s BOM Alternates enhancement jumps in to help you use those alternates.

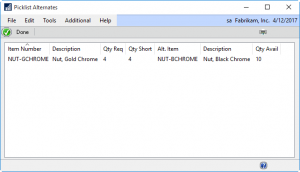

First, when a Manufacturing Order is created, if there is a shortage of the Primary Item on the Picklist, the BOM Alternates enhancement will suggest using the Alternate.

As shown above, an MO is created for SHIFT ASSEMBLY and there is a shortage of the Primary Item, NUT-GCHROME. The BOM Alternates enhancement checks if there are alternates specified for that Item on the Picklist, and if so, it checks for available inventory. Here there are 10 available, and the MO needs 4. Double-clicking on the item automatically updates the Picklist to swap the alternate in for the primary item.

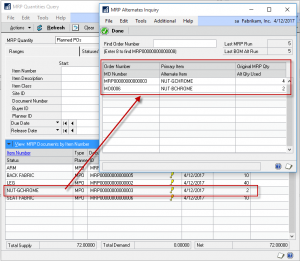

Second, the BOM Alternates enhancement integrates with MRP where it automatically adjusts suggested POs for the primary item based on availability of alternates.

The BOM Alternates enhancements pegs each Suggested PO to locate Picklist shortages which can be met with an assigned alternate. When there is available inventory of the alternate, it adjusts the Suggested PO quantity accordingly. As shown above, a shortage of the Gold Chrome Nuts was adjusted down from 4 to 2 because of available inventory of the Black Chrome Nuts.

The BOM Alternates enhancements adds a lot of useful life to the BOM Alternates setup available on the Dynamics GP Manufacturing Bill of Materials. It will help you keep production moving by quickly swapping alternates for primary items when there is a Picklist shortage, and it will reduce inventory carrying costs by driving usage of alternates before re-ordering primary items.

Product Updates

Product Updates

Blanket PO

- No changes

BOM Import

- Added checks to confirm Excel is installed and that the import file is not read only

- Fixed Create BOM Lines routine which was incorrectly setting the QTYBSUOM to 1 rather than the conversion to base when the component quantity was specified in a U of M other than the base.

Consulting Toolkit

- No changes

Engineer to Order

- Minor bug fixes regarding window redisplay issues

- Fixed issue with Overhead Costing calculation. In the process we discovered that GP Manufacturing does not calculate Overhead correctly, so ETO defaults to use the Manufacturing logic so that the ETO costing matches what Manufacturing will calculate, but ETO also includes an option to use the “correct” calculation so that the two can be compared. Please see the updated ETO documentation for a full explanation.

EZImport

- No changes

GP PowerPack

- Login Monitor: with GP2015 and later, if a user has access to only one company, the login process bypasses the Select Company window, which bypassed Login Monitor’s “During Login” check on the maximum user count. The During Login check was rewritten to account for this.

- Extended Lot Attributes: fixed error caused by closing a transaction window before saving the Lot Attributes.

- Next Number Generator: fixed issue that prevented using a numbering scheme if it did not have an alpha-prefix.

Item Process Tracking

- No changes

LabelLink

- No changes

LeanMFG

- No changes

MFG Data Archive

- No changes

MFG PowerPack

- NEW: BOM Alternates enhancements

- NEW: BOM Archive- added additional naming conventions

- Sales Forecast Integration: added cheks to the Export to Excel process to verify that Excel is installed and that it is able to create a new Workbook.

- Setup: added check to Setup window to ensure the installation has been run to prevent errors when a user opens the window via a shortcut.

- PowerATP: fixed error caused by changing the Option Set properties while focus is on a line in the ATP window.

MOGenerator

- Added check that Excel is installed (for the Excel import methods)

- Added deadlock handling to the Allocate All routine

- Core Utilities: fixed issue in the “Create MO” utilities where if the import data for the first MO to be created has an error, it caused the remaining items to also fail to generate MOs but produce no error messages.

- MO Receipt Integration: added check that MO Receipt Quantity is not zero

- MO Receipt Integration: fixed issue that caused the MO Receipt to post without consuming components when (1) it is a complete receipt against an existing MO, (2) it is marked as the final receipt, and (3) the picklist is being imported.

Preactor Integration

- No changes

SpellCheck

- No changes