The BOM Alternates enhancement provides the ability to automatically use Alternate Items when there is a shortage of the Primary Item.

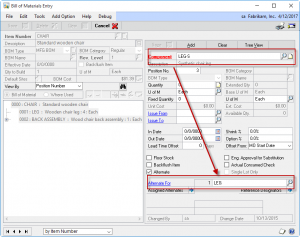

The GP Manufacturing Bill of Materials provides the ability to assign one or more Items as Alternates for a Primary Item.

As shown above, LEG-S is an Alternate for the Primary Item, LEG. When a Manufacturing Order is created, the Alternates appear on the Picklist, but Manufacturing does not use them if there is a shortage of the Primary Item, and MRP does not consider inventory of Alternates before suggesting buying more of the Primary Item.

The BOM Alternates enhancement in MFG PowerPack addresses both of these needs.

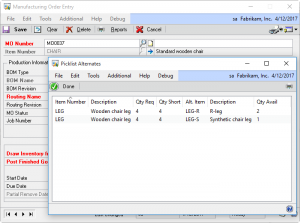

When a Manufacturing Order is created, the BOM Alternates enhancement will check if there is a shortage of the Primary Item, and then if there is available inventory of one or more Alternates. If it determines that Alternates could be used, the Picklist Alternates window automatically opens:

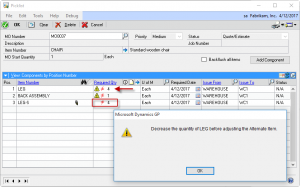

Alternate Quantities can be easily swapped by double-clicking an Alternate Item in the Picklist Alternates window. Additionally, if quantity changes are manually entered on the Picklist (i.e. increasing the quantity of an Alternate), MFG PowerPack will check that the Primary Item quantity has been reduced first. This ensures that a shortage is not left on the Picklist which could either cause MRP to order more, and that the Primary is not accidentally issued.

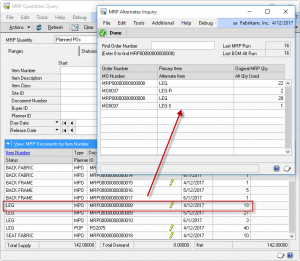

The BOM Alternates enhancement also integrates with Materials Requirements Planning (MRP), where it checks for Alternates on Picklists and adjusts Suggested POs downwards to account for usage of Alternates.

The MRP integration checks for Suggested POs which can be pegged to Picklist shortages. If there is available inventory of Alternates, it will decrease the Suggested PO accordingly.