MFG PowerPack is a Suite of modules for enhancing GP Manufacturing and its connections to Field Service, Inventory, Purchase and Sales. Within MFG PowerPack is a collection of Manufacturing Tweaks, which are smaller enhancements.

Manufacturing Tweaks:

Price $1200

- Auto-Create Routing Header: after entering the Item Number in the Routing Sequence Entry window, the system will auto-create a Primary Routing Header if one does not exist.

- BOM Entry GoTo Standard Cost Changes: adds an option to the GoTo Menu on BOM Entry to access the Standard Cost Changes window.

- Default Primary Routing: after entering the Item Number in the Routing Sequence Entry window the Primary Routing will display automatically.

- Edit MO Status Allocation Override: Automatically override shortages (if system setup allows for this), when Releasing Manufacturing Orders.

- Edit MO Status Options: When working with MO Planned Orders in the Edit MO Status window, this Tweak adds the ability to (1) Select which Scheduling Preference to use when Creating MOs, and (2) Override the default MO Description (which normally is set to the MRP-MO Number) with a user entered value.

- FIX-BOM Category Rolldown: prevents a bug in the Bill Of Materials window that results a change to the BOM Category field rolling down to every record in the BOM Lines table.

- FIX-Calendar Years: The Manufacturing Shop and Work Center Calendars only have years through 2026. The Calendar Fix will increase that so the “years” dropdown list will always have 10 years into the future (User Date plus ten years).

- FIX-MFG Note Duplicates: The MFG module has two procedures for getting the “next note index” when you add notes in different locations. Depending on which window you are on when you add a note it will result in a duplicate note index (i.e. the same note will appear on at least two records). The MFG Note Fix ensures that the MFG module always uses the correct method to get the next note index and therefore prevents creating duplicate notes.

- FIX-Past Due Sales Forecast: MRP is not able to see past due Sales Forecast demand regardless of any MRP settings. The Past Due Sales Forecast fix corrects this issue in MRP.

- Equipment Zooms: If Field Service is installed, Additional Menus are added to several Serial Number Inquiry windows to provide quick access to the Field Service Equipment Record.

- Force Reschedule: The Manufacturing Order Entry window only allows Scheduling/Rescheduling an MO if the MO Status is Quote or Open. When an MO is Released (Hold or Partially Received) it will not allow Rescheduling unless the Status is changed back to Open, and that cannot be done if there is activity on the MO such as a Component Issue. This Tweak overrides those controls and allows Rescheduling an MO in Released, Hold or Partially Received Status.

- Indented BOM Report: creates an exploded Bill of Materials report from the BOM Maintenance window, showing each subassembly indented below its parent.

- Item LLC Recalc: adds the ability to perform a single item LLC recalculation from Item Engineering, and also automatically recalculates the Item used in a BOM Mass Update.

- Item Maintenance GoTo BOM: adds a GoTo menu option on Item Maintenance to open the Manufacturing Bill of Materials.

- MO Date Default: Automatically populates the Start Date (or End Date) on the MO Entry window based on per-item settings so that it does not always default to 00/00/0000.

- MO Lookup-Save Settings: Remembers the last used settings, on a per user basis, for the MO Lookup Sort By, MO Status, and Outsourcing dropdowns. The saved settings will be reapplied the next time the window opens.

- MFG Note Fix: The Manufacturing module has two procedures for getting the “next note index” when you add notes in different locations. Depending on which window you are on this will create a duplicate note index. The MFG Note Fix ensures that the MFG module always uses the correct method to get the next note index and therefore prevents creating duplicate notes.

- MO Receipt Outsourcing Warning: when creating an MO Receipt, it checks for Outsourcing Purchase Orders that have not been received, and warns the user if one exists.

- MO-SO Receipt Warning: This tweak is intended to address an issue with the Manufacturing Order Receipt Entry window where is does not consider MOP-SOP Links and will post a receipt when the SOP Document is in use.

- MRP Query Default: Create an MRP Quantities Query to store values such as the MRP Quantity (i.e. ATP Total), a Site restriction and a Planner ID, and have that Query pull-up automatically when the MRP Quantities Query window opens.

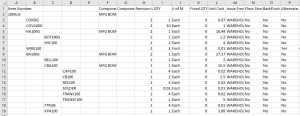

- PO Gen Integration: PO Generator suggests purchase orders based on quantities in the Item Quantities Master table. However, there are modules, such as GP Manufacturing and Field Service, that create transactions which do not update the Item Quantities until after the transaction posts (for example, unallocated Manufacturing Picklists or unreceived Inter-Site Transfers). PO Gen Integration can pull additional sources of inventory supply and demand into the PO Gen calculation to arrive at more accurate purchasing suggestions.

- PO Gen Remove MO: PO Generator does not consider quantities being made on Manufacturing Orders when it creates PO suggestions. This tweak provides an integration between PO Generator and Manufacturing so that the Quantities on MO are visible in PO Generator, and also can be automatically subtracted from suggested PO quantities.

- Post Data Collection Journal Entries: Data Collection, Automated Data Collection, and data collection integrated into the ADC_Input_Records (SF010500) table all create Journal Entries that need to be manually posted through the GL Batch or Financials Series Post windows. This Tweak will automatically post those Journal Entries. Posting Journal printing is suppressed so the posting can happen in the background without user interaction. This is particularly important when using the ADC Processor.

- Posting Journal Settings: adds setup options to control whether or not the posting journals print when posting an Manufacturing Component Transaction (Issue/Reverse Issue), a Manufacturing Order Receipt, or Manufacturing Order Close.

- Purchase Request Resolution GoTo MRP Workbench: Adds an item to the GoTo button on Purchase Request Resolution that opens the MRP Workbench window. The Item Number and Site ID selected in the Purchase Request window will be display in the MRP Workbench window.

- Prevent MO Delete: ensure a contiguous sequence of MO Numbers by preventing users from deleting MOs.

- Remember MO: remembers the last used MO Number on MO Entry so you can use the GoTo to access multiple windows without having to re-enter the MO Number.

- Revaluation Detail: When the Rollup and Revalue process creates a Journal Entry there is no reference on the distributions to the Item Number. This Tweak captures the Item Number, Location Code and Quantity on Hand used in the Revaluation Calculation and stores it along with each distribution on the revaluation Journal Entry.

- SOP Copy Create MOP-SOP Links: The GP SOP Copy utility does not create default MOP-SOP Records (IS01001) which prevents the copied transactions from being visible to MRP. This tweak creates the default MOP-SOP Records when SOP Copy adds lines to a document.

- SOP Transfer – Keep Date: normally when a sales document is transferred, GP resets the In-House Due Date and Customer Promise Date to be the same as the Requested Ship Date. This Tweak ensures the dates retain their original values during document transfer.

- Suppress MFG SOP Detail When Not Short: normally when a sales document is transferred, GP resets the In-House Due Date and Customer Promise Date to be the same as the Requested Ship Date. This Tweak ensures the dates retain their original values during document transfer.

- SVC RMA Rolldown Site: adds an option, when changing the Site ID on the RMA Header, to roll-down the new Site to all of the lines on the RMA.

- Turn Off Job Cost Menus: The Job Costing module in GP Manufacturing adds right-click menus to many windows in GP which replace the normal right-click menus that provide access to Insert Row, Delete Row, Cut, Copy, Paste, etc. This Tweak turns off the Job Cost Right-Click Menus so that GP can display the normal menus.

- Unlink MO from SOP: The normal process required to unlink an MO from a Sales Line requires several steps and must be performed one MO at a time. This tweak adds an Additional Menu to Sales Transaction Entry that allows quickly unlinking one MO from a line, or all MOs from the document.

- Use MO Number for IV Doc Number: causes Manufacturing to create Inventory Transactions using the MO Number for the IV Document Number. For example, the first Receipt of MO1234 will create Inventory Adjustment MO1234*1.

- Use SOP Number for MO Number: causes Manufacturing to create Manufacturing Orders from Sales Transaction Entry using the SOP Number for the MO Number. For example, the first line item on ORDST2237 would result in MO Number ORDST2237#0001.