V12.0.84 / 14.0.59 / 16.0.37 / 18.0.4

* MORI: (1) MO Query-addressed issue that could cause the query to not save, (2) Override IV Doc Number with MO#-this new user preference setting on the MOGen window causes MORI to override manufacturing when it creates Inventory Adjustments. Instead of using the default Next IV Adjustment Number, the adjustment will be created using the MO# plus a suffix for each subsequent Adjustment (such as MO00123*1, MO00123*2, MO00123*3 and so on). This option was added to address a condition reported in very high volume environments with multiple MORI processors where the normal GP logic that generates the Next IV Document Number allows two nearly simultaneous processes to receive the same Document Number.

Author: admin

GPPowerPack Release 2018-07-24

V12.0.123 / 14.0.66 /16.0.34 / 18.0.6

* TWK-SOP: Auto-Open Customer Detail: addressed issue that caused Customer Detail Entry to pop behind SOP Entry if user clicked on Customer Detail Entry with the mouse rather than using the keyboard (#20184512)

* TWK-SOP: Display Ship Weight in Title Bar: added a setup option to control whether shipping weight for kits comes from the Kit Item or the Components.

MFG PowerPack Release 2018-07-23

V12.0.136 / 14.0.83 / 16.0.49 / 18.0.10

* Serial/Lot Mass Generate: addressed issue that caused the Next Lot Number to not increment to the last lot number when generating multiple lot numbers for a receipt.

MOGenerator Release 2018-07-16

V12.0.83 / 14.0.58 / 16.0.36 / 18.0.3

* MORI: (1) Error Log- added button to “hide” errors. This changes records errors to a new status code so they are no longer displayed in the error log window. (2) Changed how conversion to Base UofM is handled in the MOPick table to account for a UofM Schedule that has circular conversions. (3) Changed timing of when a “split” MO is created during a partial receipt so that all errors checks must pass before the split MO is created. (4) Added Edit MORI Data window (accessible from Error Log window GoTo button) to facilitate manually changing data in the MORI tables from inside GP.

Consulting Toolkit Release 2018-07-16

V12.0.20 / 14.0.14 / 16.0.10 / 18.0.2

* Virtual Triggers: (1) Added green/red dot in Lookup to indicate active/inactive, made window wider so entire Trigger ID can be viewed, (2) Increased size of Trigger ID and Trigger Desc fields.

MFG PowerPack Release 2018-07-13

V12.0.135 / 14.0.82 / 16.0.48 / 18.0.9

* Item Copy: addressed issue that caused an Illegal address for field Start Intercompany ID error (#20184420)

Trying Our Software

In additional to being fully functional in Fabrikam, all of our software is also fully functional, without registration keys, in <TEST> companies. There are two benefits from this:

First, you can download and test our software using your live data without needing a temporary, time-limited key.

Second, if you already have our software but are not registered for all of its features, you can test ALL functionality in the <TEST> company without changing your registration key.

In short, all functionality of all of our modules is always available in a <TEST> company.

In case you are not familiar with a <TEST> company, here’s a quick overview.

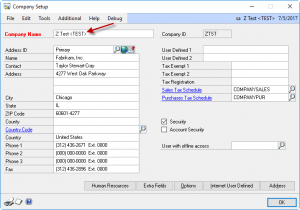

Dynamics GP has a little feature that is not well documented, which provides support for Test and Historical company databases. To enable this feature, put <TEST> or <HISTORICAL> at the end of the Company Name, as shown below:

<TEST> must be placed at the end of the Company Name (i.e. “WilloWare Inc. <TEST>”).

The primary effect of this is that it Zeros the Employee Count so the Employees in a TEST or HISTORICAL Company do not affect payroll.

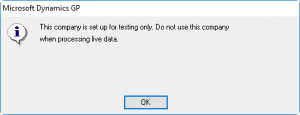

It also causes a warning to pop-up during login to help alert users that they are not in the live company:

And, it will also cause WilloWare software to enable full functionality.

NOTE: During log-in you will receive a warning that the software is not registered.

LabelLink Release 2018-07-12

V12.0.38 / 14.0.21 / 16.0.10 / 18.0.3

* Addressed issue that could prevent software from recognizing the registration key.

LeanMFG Release 2018-07-10

V12.0.33 / 14.0.22 / 16.0.12 / 18.0.4

* Disassembly: addressed issue that prevented selecting a “split lot” for disassembly.

MFG PowerPack Release 2018-07-09

V12.0.134 / 14.0.81 / 16.0.47 / 18.0.8

* Item Copy: addressed issue that prevented the Excel Import utility from creating new Items when the spreadsheet did not contain additional columns (E and beyond).

* Quick Disassembly: addressed issue that caused “Illegal address for field ‘Reason Code'” when user closed window while it was processing the disassembly (#20182763).

* Service Equipment Suite: added check that SVC Setup has been completed before enabling SVC Equipment Suite.

Grant SQL All Objects

It is commonly thought that the grant.sql script (found in the GP Folder\SQL\Utils\) takes care of security at the SQL Server level by granting access to DYNGRP to all of the SQL objects used by Dynamics GP.

It doesn’t!

We recently had a support case where the user was getting the following error:

The EXECUTE permission was denied on the object ‘MFG_FUNC_Component_BOM_Type’

The function is part of the Manufacturing Module, but our Export Indented BOM feature in MFG PowerPack uses the function.

We asked the client to run grant.sql to fix the issue. The user still had the error.

At that point we knew there were only two options: (1) the User ID wasn’t assigned to DYNGRP, or (2) there was something wrong with grant.sql.

A quick look at grant.sql and the problem was obvious–it grants security on Tables, Views and Stored Procedures. It does not grant security to Scalar Functions or Table Valued Functions.

An updated GRANT.SQL script is below. It covers all of the SQL objects listed above.

Download GrantAll.zip (it contains a text file): GrantALL

MFG Data Archive Release 2018-06-20

V12.0.24 / 14.0.15 / 16.0.10 / 18.0.1

* First GP2018 Release

* Added new tables to the archive. If an MO has already been archived using a prior build, the archive routine will “catch up” on the new tables the next time the archive utility runs. The new tables are:

MOP1003 – MOP_MOVar_HIST

MOP1004 – MOP_MO_Variance_Material_Hist

MOP1006 – MOP_Item_MSTR_Qty_Var

MOP1009 – MOP_WIPCostChanges

MOP1012 – MOP_MO_Variance_Material_Hist_STD

MOP1015 – MOP_WIPOverrideHist

MOP3000 – MOP_Variances

* New Archive Processor window: a new bulk copy archive routine achieves a significant decrease in the time required to archive MOs.

* New locally installed PDF documentation, and context sensitive CHM help

GPPowerPack Release 2018-06-19

V12.0.122 / 14.0.65 /16.0.33 / 18.0.5

* Extended Lot Attributes: addressed issue that caused ‘incorrect syntax error’ when creating of the lot attributes.

LeanMFG Release 2018-06-13

V12.0.32 / 14.0.21 / 16.0.11 / 18.0.3

* Install/Upgrade: added checks for temp tables remaining from a prior upgrade to prevent an attempt to re-upgrade the tables (#20183874)

* MO Entry: addressed Illegal address for field ‘BuildPicklist’ in script ‘AbortForShortages’ error caused by closing window while picklist is being built (#20183844)

Blanket PO Release 2018-06-06

V12.0.33 / 14.0.22 / 16.0.8 / 18.0.1

* First GP2018 Release

* Blanket POs can now be printed from the PO Inquiry Zoom window

* Updated WW Internal Resources

* New locally installed PDF documentation, and context sensitive CHM help

LabelLink Release 2018-06-03

V12.0.37 / 14.0.20 / 16.0.9 / 18.0.2 Changes 3-JUN-2018

* Updated WW Internal Resources

GP PowerPack Release 2018-05-29

V12.0.121 / 14.0.64 /16.0.32 / 18.0.4

* SOP Doc Print Options Defaults: addressed issue that caused field not found error is user quickly closed the Sales Print Options after it opened (#20181312)

* Extended Lot Attributes: (1) Addressed issued that cause ELA to not save the core GP attributes on an MO Receipt, (2) Connected ELA to Manufacturing PowerPack’s Serial/Lot Mass Generate Utility. ELA will now open for each Lot created by SLMG.

MFG PowerPack Release 2018-05-29

V12.0.133 / 14.0.80 / 16.0.46 / 18.0.7

* Serial/Lot Mass Generate: integrated into GP PowerPack’s Extended Lot Attributes. If ELA is registered and enabled, the ELA Attribute Entry window will pop-open for each Lot Numbered generated.

* Quick Disassembly: changed routine that retrieved average cost for the actual cost raw materials to use a weighted average, and also take into account reverse issues.

SpellCheck Release 2018-05-10

V12.0.22 / 14.0.13 / 16.0.10 / 18.0.2

* Addressed issue that caused SpellCheck to close other open instances of Word (#20182401)

GP PowerPack Release 2018-05-09

V12.0.120 / 14.0.63 /16.0.31 / 18.0.3

* idModifier: added new feature that allows adding user-defined ID Types so that idModifier can be used to change IDs from 3rd party products, or other previously undefined ID Types.

MFG PowerPack Release 2018-04-18

V12.0.132 / 14.0.79 / 16.0.45 / 18.0.6

* Quick Disassembly: addressed duplicate key error when looking up an MO Number for disassembly (#20181122)

CompleteCount Release 2018-04-13

V12.0.31 / 14.0.21 / 16.0.14 / 18.0.4

* Addressed issue in the Stock Tag Variance report that caused it to include all started Counts rather than only selected Counts (#20180765)

* Updated WW Internal Resources

LeanMFG Release 2018-04-12

V12.0.31 / 14.0.20 / 16.0.10 / 18.0.2

* Addressed error “Invalid length parameter passed to the LEFT or SUBSTRING function” during installation when the Batch Header table has records with blank Batch Numbers (#20181010)

Item Process Tracking Release 2018-04-11

V12.0.13 / 14.0.8 / 16.0.4 / 18.0.1

* First GP2018 release

* Deployed new help system that provides local context sensitive CHM help, local PDF documentation, and online web-help

LeanMFG Release 2018-04-09

V12.0.30 / 14.0.19 / 16.0.9 / 18.0.1

* First GP2018 Release

* Item Engineering: (1) creating Item Engineering records is now REQUIRED. Missing Item Engineering records will generate a warning to that effect if they are used in MO Entry.

* MO Entry: (1) Addressed issue in posting that left empty batch records in Batch Header/SY00500 (#20180802). (2) Added routine during installation that checks for empty LeanMFG batches and removes them. (3) Addressed issue that caused “selected record has been deleted by another user” error after clicking the Build Picklist button. (4) Added posting indicator that appears on the window while the posting process is running. (5) New posting routine prints Transaction Posting Journals rather than Inquiry Journals.

* Vendor Approval: NEW- Vendor Approval functionality. Enabling Vendor Approval will require that a Vendor is approved for purchase of an item before the item will be allowed on a PO.

* Added additional controls to keep LeanMFG transactions from being viewed in IV Transaction Entry.

* Doc Type Details: (1) Changed labels on Journal Printing options, (2) New Option: Show Unit Cost Warning–if enabled, shows a warning message if posting Output(s) would create split cost layers because the input costs do not divide evenly into the Output unit cost.

* New locally installed PDF documentation, and context sensitive CHM help

MFG PowerPack Release 2018-03-26

V12.0.131 / 14.0.78 / 16.0.44 / 18.0.5

* Quick Disassembly: (1) Added support for disassembly using a Manufacturing Order as the source, (2) Added support for Inventory Reason Codes on the Quick Disassembly window.

* PowerATP: (1) Added logic to handle an Intersite Transfer created by an RTV where the Return Item is different than the Out Item (#20180797). (2) Added exclusion for SOP Voids so the ATP query does not catch them while they are being moved to history (#20180081)

* Serial Mass Entry: (1) Addressed issue in Item Transaction Entry that caused the Total Serials Selected to display the Quantity Required

* Indented BOM Report: (1) Added more columns, (2) Added new BOM Export Query window from MFGPP Setup to allow editing the query so that columns can be added/remove/renamed or additional tables joined to the query.

MOGenerator Release 2018-03-27

V12.0.82 / 14.0.57 / 16.0.35 / 18.0.2

* MORI: addressed issue that caused GP to crash when MORI attempted to process a very large number of MO Receipts all of which have errors.

MFG PowerPack Release 2018-03-26

V12.0.130 / 14.0.77 / 16.0.43 / 18.0.4

* Serial/Lot Mass Generate: (1) Addressed issue that caused Next Lot Number to not increment correctly if a Global Lot Number was not being used. (2) Added warning if Global Serial/Lot Number functionality is enabled and Item Class Serial/Lot Numbering setup exists (the features should not be used at the same time)

* Item Class Serial Numbering: (1) renamed to Item Class Serial/Lot Numbering and extended its functionality to Lot Numbers. (2) Added warning if Global Serial/Lot Number functionality is enabled and Item Class Serial/Lot Numbering setup exists (the features should not be used at the same time)

* Updated WW Internal Resources

MFG Import Release 2018-03-24

V12.0.40 / 14.0.23 / 16.0.11 / 18.0.4 Changes 24-MAR-2018

* Updated WW Internal Resources- addressed issue opening help files

Consulting Toolkit Release 2018-03-23

V12.0.19 / 14.0.13 / 16.0.9 / 18.0.1 Changes

* First GP2018 release

* Addressed issue with Database Manager’s Server Properties window that prevented it from reading the properties.

* Documentation rewrite. Deployed new Help system.

LabelLink Release 2018-03-21

V12.0.36 / 14.0.19 / 16.0.8 / 18.0.1

* First GP2018 release

* Addressed issue that could cause no labels to print from Sales when the SOP Header contains a bad SOPTYPE

* Item-Label Setup: added new functionality to allow associating a label with one or more Item Numbers. When that label is selected in the LabelLink window it automatically restricts the view to show only items covered by the selected label.

* Updated WW Internal Resources

SpellCheck Release 2018-03-19

V12.0.21 / 14.0.12 / 16.0.9 / 18.0.1

* First GP2018 release

* Added “Templates” on the Setup window to provide quick setup of common SpellCheck locations

MOGenerator Release 2018-03-14

V12.0.81 / 14.0.56 / 16.0.34 / 18.0.1

*First GP2018 Release

* MORI: (1) Added new receipt posting process tracking to ensure MO Receipts are posted one at a time, and that posting has time to finish before the next MO Receipt is started. Removed the “in batches of” setting as MORI will now run continuously untill all pending receipts have been processed before it enters its timer-mode to wait for more records. (2) The Date column in MO Hdr is now being used (previously it was not used) with the new MO Query functionality. (3) Cancel button now terminates all processing immediately after the current MO finishes. (4) By Products are now supported for non-serial/lot tracked components. (5) Added new Setting “Delete MORI Record After Import”. When marked, if an MO Receipt processes OK it will be cleared from the MORI tables.

* MOGen:(1) CreateMOs & MOP-SOP Link: when importing from Excel, SOP Number and Line can now be provided to have the utility create a MOP-SOP Link. There is also a new SQL table for importing MOP-SOP links. (2) Added new Setting “Delete File After Import”. When enabled, MOGen will delete the excel file after importing the contents. (3) MO Description, BOM Type, and Schedule Method have been added to User Settings (they are remembered across sessions). (4) Create Child MOs: addressed an issue that caused the utility to run when the Create Child MOs box was not marked on MOGen, but the Setup option to Create Child MOs from SOP was marked.

* MO Query: New MO Query window has selection options to control which MO Receipts are processed. The MOHdr Date column can be used to only bring in MOs on or before the GP User Date. The window can also build complex, multi-parameter queries to restrict which records are pulled-in by the processor. The MO query can be used when running multiple MORI processors to ensure each one only handles certain types of records.

* MO Gen Error Log: added go-to button to access Picklist Shortages Inquiry, and MO Activity Inquiry.

* Documentation: complete rewrite, and deployment of local CHM help, PDF help, and webhelp.

MFG Import Release 2018-03-12

V12.0.39 / 14.0.22 / 16.0.10 / 18.0.3

* BOM Import Map: (1) Added radio buttons to change map view to BOM Header fields or BOM Line fields

* BOM Import: (1) Added check for multiple Rev Levels of same BOM in same file, (2) Added check for PPN having itself as a CPN, (3) Added check for first row missing Parent Item, (4) Added imported line count on window

* Updated WW Internal Resources

CompleteCount Release 2018-02-28

V12.0.30 / 14.0.20 / 16.0.13 / 18.0.3

(1) Mass Add/Update: addressed issue that caused ‘multi-part identifier could not be bound’ error when multi-bins was not enabled (#20180493)

(2) Updated WW Internal Resources

CompleteCount Release 2018-02-15

V12.0.29 / 14.0.19 / 16.0.12 / 18.0.2

(1) Mass Add/Update: addressed issue that would prevent the window from adding a new Item-Site-Bin combination to the Stock Count if the Item-Site pair already existed on the Stock Count.

(2) Updated WW Internal Resources

GP PowerPack Release 2018-02-12

V12.0.119 / 14.0.62 /16.0.30 / 18.0.2 Changes 12-FEB-2018

* Addressed issue that caused Shortcut Bar navigation to not display when GP PowerPack was installed and the user either had the “remember company” checkbox marked, or the user had access to only one company. Also, if the above conditions existed but the INI file contained the switch ScriptDebugger=true, then the Shortcut Bar navigation would appear as it normally does, but changing to ScriptDebugger=false would make the navigation disappear.

GP PowerPack Release 2018-02-09

V12.0.118 / 14.0.61 /16.0.29 / 18.0.1 Changes 9-FEB-2018

* First GP2018 Release

* Extended Lot Attributes: added support for Assembly Transactions

* System Access Lock: (1) added DYNSA to the Always Allowed list, (2) added an additional login control to prevent users from accessing a locked database if there is one database or they have marked Remember Company.

* Select Checks Filters: changed how the Filter appends multiple values depending on the “Compare Option” is “Does/Is” or “Does/Is Not”. “Does/Is” will still append values with “OR”, such as Batch ID Begins with “A” or Batch ID Begins with “B”. “Does/Is Not” will now append values with “AND”, such as Batch ID Does Not Begin with “A” and Does Not Begin with “B”.

* Updated WW Internal Resources

MFG PowerPack Release 2018-01-30

========== Change History ========

V12.0.129 / 14.0.76 / 16.0.42 / 18.0.3

* Vendor Pricing Import: addressed issue that caused it to not report an error when the file included duplicate pricing lines (#20180219)

* BOM Alternates – Picklist: addressed issue that caused the window to display Use Up items when there was no quantity available

* PowerATP: added button to access MFG Pegging window.

BOM Import Release 2018-01-19

========== Change History ========

V12.0.37 / 14.0.20 / 16.0.8 / 18.0.1 Changes 19-JAN-2018

* First GP2018 Release

* Added Routing Import

* BOM Import: (1) Added map field for Routing Name when using Routing Template Items, (2) all import strings now have leading/trailing spaces removed

* Updated WW Internal Resources

More Detail…

BOM Import now contains a Routing Import utility. Features include:

- Map a spreadsheet to routing fields

- Most fields can be populated with default values

- Can import routing sequence notes

- Automatically pads the Sequence Number to the desired number of digits

- Can import OpCodes. The import will then populate the routing sequence values (i.e. Setup Time, Setup Labor Code, Labor Time, Labor Code, etc) from the OpCode

GP PowerPack Release 2017-12-21

V12.0.117 / 14.0.60 /16.0.28 Changes

* SOP Require Customer PO: addressed issue that resulted in an inability to manually key-in a SOP Number when first opening the window (#20180064)

* Mass Batch Change: created a more user-friendly error message when the query contains errors (#20180079)

* System Access Lock: added to Setup window so it does not automatically enable based on registration key.

* PO Document IDs: addressed issue that caused the default GP Next PO Number to increment when using a PO Doc IDs.

* IV Mass Transfer/Transaction: addressed ‘illegal address’ error caused by closing the Item Transfer or Transaction window before clicking Create on the Mass Transfer/Transaction window.

MFG PowerPack Release 2018-01-12

V12.0.128 / 14.0.75 / 16.0.41 / 18.0.2

* BOM Alternates: (1) added controls to prevent Item Egineering from clearing/locking the Use Up field, (2) Picklist Alternates now does not attempt to open MCTE if it just Released the MO and Mfg Setup has “allocate on release” enabled.

* Lead Time Inquiry: (1) added Qty On Order, (2) zooms on Qty Allocated and Qty On Order

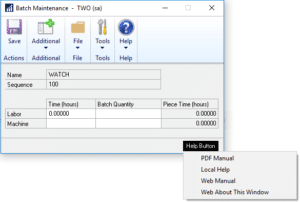

New Help Buttons

As we roll-out new builds for GP2018, we are adding new Help functionality to all of our products across all currently supported GP versions (at this time we are supporting GP2013 through GP2018). There were four goals for the new Help. The new Help should…

- Be easy to access

- Make it easy to locate relevant information

- Be available to both desktop and web clients

- Provide the most current information about the product

The new Help (shown above) is available via a black “Help Button” on every WilloWare window. It provides access to:

- The PDF Manual

- Local Help. This is a context sensitive CHM Help File that will open to a section of the Help File containing information about the current window.

- Web Manual. This is a web-based product manual. Since the PDF Manual and the Local Help file can only be updated by installing a new build of the software, they may not contain the most current information. The Web Manual is updated as needed to provide the most current and complete documentation.

- Web About This Window. Web-based context-sensitive Help that retrieves a section from the web-manual that pertains to the current window.

MFG PowerPack Release 2018-01-05

V12.0.127 / 14.0.74 / 16.0.40 / 18.0.1

* First GP2018 Release

* Serial Number Mass Entry: (1) Fixed Done button on Rejects to it closes the window. (2) When adding serials, the check that verifies if a serial already exists in GP previously used sql queries to mass update the ‘new serials’ table. This method was fast when checking a large quantity of serials, however, since it only queried known tables, it missed 3rd party products. The check has been changed to use an Inventory module function, which is also used by integrating products to make GP aware of serials in the 3rd party product. This method requires checking each serial one at a time, which is slower, but ensures it is aware of serials in 3rd party products.

* BOM Alternates: (1) added controls on BOM Entry window, (2) restricted MRP Alternates to only pick up “Use Up” items

* New HELP: each window provides access to the PDF Manual, Context sensistive CHM Help, Web-based Manual, and Web-based context sensitive help

GP PowerPack Release 2017-12-21

V12.0.116 / 14.0.59 /16.0.27

* Next Number Generator: addressed issue that could cause a get/change error on wNextNumTags (#20176716)

* U of M Schedule Change: addressed issue in IV30300 conversion that caused invalid column error when a comparable UofM could not be located and the quantity needed to be converted to the Base UofM (#20177104)

* Updated WW Internal Resources

CompleteCount Release 2017-12-19

V12.0.28 / 14.0.18 / 16.0.11 / 18.0.1

(1) Upgrade to GP2018

(2) Mass Add/Update: added view that shows Tolerance values when performing the Tolerance update

(3) Tag Submit: addressed issue in Item Allocation routine with bins that caused incorrect calculation of quantity counted in the bin

(4) New Reports: New Item-Site, New Site-Bin, New Item-Site-Bin

(5) Tag Reports window: (1)changed from list view to scrolling window to improve performance for all “Tags” reports (2) “Tags” reports can now be printed with a GP Report Writer report rather than exporting to Excel

(6) Help: (1) each window now provides access to the PDF manual, CHM context sensitive help, Online manual, and Online context sensitive help

(7) New 2-Wide by 4-Down stock tag

MOGenerator Release 2017-12-13

V12.0.80 / 14.0.55 / 16.0.33

* Create Child MOs: a change made in builds (v12.0.57 / 14.0.32 / 16.0.10) to create Child MOs based on the picklist of the parent, rather than the BOM, dropped the “excluded items” check. Excluded Items has been re-enabled.

MOGenerator Release 2017-12-12

V12.0.79 / 14.0.54 / 16.0.32

* Create Child MOs: addressed an issue in the link to SOP Configurator that prevented it from creating child MOs with a configured BOM.

MFG PowerPack Release 2017-12-09

V12.0.126 / 14.0.73 / 16.0.39

* Capable To Promise: fixed issue in BOM Qty calculation that caused incorrect Qty In Base calculation for components (#20176904)

* BOM Alternates – Picklist: added auto-release of MO after selecting alternates, and auto-creation of MCTE Allocation Transaction.

CompleteCount Release 2017-12-08

V12.0.27 / 14.0.17 / 16.0.10 Changes

(1) Mass Add: addressed issue that cause a duplicate key error when the bin table contained Qty Types other than On Hand (#20176937)

(2) NEW: added a new 2-wide stock tag report option