Customization CR1327

Fuel Surcharge

Description of Need:

ACME needs to apply a fuel surcharge to sales orders and invoices. This fuel surcharge will be a percentage of the sales subtotal.

Description of Solution:

Navigation: Tools>>Setup>>Sales>>Surcharge Setup

| Field | Function |

| Fuel Surcharge | Enter the fuel surcharge that will be used as a percent |

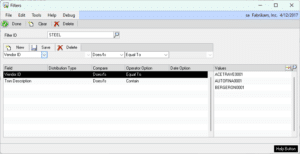

Customer Maintenance

The Customer Maintenance window will be updated as follows:

| Field | Function |

| Fuel Surcharge | This is an existing User Defined 1 Field. ACME will use the Receivables Setup window to relabel it. The enhancement will read the number entered here as the fuel surcharge percent as entered.

To charge 6%, the user must enter 6, not 0.06 |

| Checkbox | This will be a virtual checkbox, meaning the window itself will not be modified. The custom fuel surcharge will only be applied if this checkbox is marked, otherwise it will default to the value in setup. If this box is marked, but no value is entered into Fuel Surcharge, the default amount will be used. |

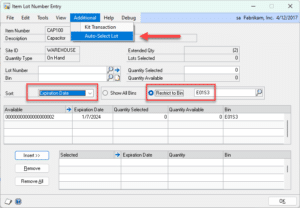

Sales Transaction Entry

The Sales Transaction Entry window will be updated as follows:

| Field | Function |

| RECALC | This will be a virtual button, meaning the window itself will not be modified.

Clicking the RECALC button will recalculate the fuel surcharge using the logic detailed below. After the Fuel Surcharge field is updated, the Tax and Totals fields will also be updated. |

| Fuel Surcharge | The Miscellaneous field will be relabeled to Fuel Surcharge. |

As items are added to a Sales Order or Sales Invoice, the fuel surcharge will automatically recalculate each time the Subtotal is changed.

The Fuel Surcharge is calculated using the following formula:

Surcharge = Subtotal * % from either Customer Card or Setup, as indicated above.

NOTE: If the customer maintenance setting for using a custom fuel surcharge changes at any time during the life cycle of the order, the next time the Fuel Surcharge logic is applied it will use the new settings.

The Fuel Surcharge can also be applied/ updated by clicking the new RECALC button added to the Sales Transaction Entry window.

The user can manually override the fuel surcharge by entering a new value. If a value is manually entered, adding additional items or clicking the RECALC button will override it if clicked again.

If the user needs to exclude the document from being charged a fuel surcharge, an Additionals menu option will be added to Sales Transaction Entry. Click Additionals >> Exclude Fuel Surcharge.

When Exclude Toggle Fuel Surcharge is selected, the Fuel Surcharge field will be cleared and disabled. No fuel surcharge can be added to the document.

To Re-enable the use of Fuel Surcharges on that document, click the Additionals >> Exclude Fuel Surcharge option again. This will bring the document back to the state where a fuel surcharge can be calculated once more.

Assumptions/Requirements:

- The functionality described above will not work with eConnect, any software that uses eConnect, or any software that directly writes to, updates, or deletes from SQL tables.

- The functionality described above is intended for the GP Desktop client.

- National Accounts functionality is NOT used.

- Advanced Distribution functionality is NOT used.

- Unless otherwise noted in this document, reporting is not included in this estimate.

- Unless otherwise noted in this document, Word Template functionality is not addressed.

- Unless otherwise noted in this document, the enhancement will not integrate with 3rd party products. Some examples of 3rd party products would be:

- An ISV plug-in product including WilloWare products

- A dexterity customization designed by another developer

- Dynamics GP Modules including, but not limited to:

- Project Accounting

- MDA

- Analytical Accounting

- Copy functionality found in SOP, POP and Inventory

- Field Service

- Extended Pricing

- Manufacturing

For information on this design, or any other WilloWare customization or product, please contact us: