Release Date: 5-MAR-2024

GP Versions: 12/14/16/18

LeanMFG Build: 3.58

* MO Entry: fixed issue with cost allocation to finished good that occurs when the components have more currency decimals than the finished good. This applies to systems where Multicurrency is NOT enabled and currency decimals on the output item is less than the input item(s), or Multicurrency IS enabled and the Item Currency decimal places setting for the functional currency with the Output item is less than the Item Currency decimal places setting for the input(s).

* Added label to GoTo buttons for better appearance with Action Pane menus

* This release will notify POWERUSERs when there is a new version of the software available for download.

Author: admin

MFG Calendar Date Fix

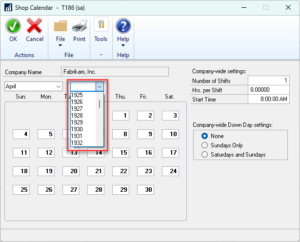

The Manufacturing Calendar windows (Shop Calendar and Work Center Calendar) are funny. Have you ever looked at the years available in the “years” dropdown list?

The list starts with 1925! Great Plains (what is now Dynamics GP) was not even created until at least 1930 and even way back then manufacturing planners had figured out that you cannot schedule work in the past.

Seriously though, consider that the list of years is “hard coded”–the original developer typed all of those years into the list when the window was created 90s, and look how far into the future it goes:

Yup, 2026. So, somebody sat there and typed 100 years into that dropdown, filling it mostly with historical years that would not be used, and then only went forward to 2026.

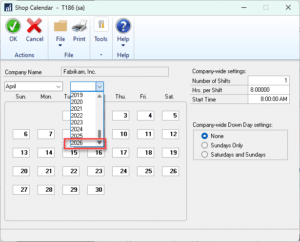

What is even more astounding is that a developer can write a tiny bit of code to populate the dropdown list at the moment the window opens. So instead of entering 100 years one at a time, you could have a bit of code that says: start today, count to 10 adding +1 to the year each time. That’s it! Now the list starts at today and goes forward ten years, and it will always do that.

Well, here we are getting close to 2026, the list is hard-coded and you are going to need to schedule manufacturing orders. WilloWare’s got your back!

We just added a new TWEAK to MFG PowerPack called “Calendar Fix”. The Tweak adds years to the drop-down so it goes out 10 years (User Date plus 10 years). The Shop Calendar and Work Center Calendar are both covered by Tweak.

Lastly, the above situation is still true as of Dynamics GP build 18.6.1685, and any version of GP prior to that.

MFGPowerPack 2024-03-01

Release Date: 01-MAR-2024

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.234

* NEW: MFG Tweak-Shop Calendar Year Fix- the MFG Shop Calendar “years” dropdown only goes to 2026. Enabling this fix will populate the Years dropdown to the User Date plus 10 years.

MOGenerator 2024-02-22

Release Date:22-FEB-2024

GP Versions: 12/14/16/18

MOGenerator Build: 4.133

* Fixed issue with Action Pane style menus that caused GoTo buttons to navigate incorrectly

* MOGenV2: fixed issue in rescheduling routine that forced picklist rebuild

Declutter SmartList

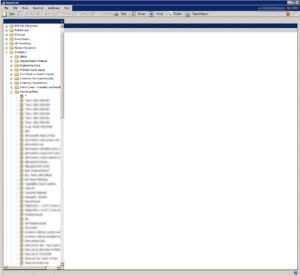

SmartList is a wonderful tool! It makes it so easy to explore your GP data and once you get the desired columns, in the right order, with the Search Criteria you need you can save it as a Favorite for quick access.

And when you need to look at things slightly differently you create another Favorite. So does everybody else. Maybe somebody leaves the company and the new person does not know what all of the old Favorites do, so they create new ones. Eventually your SmartList looks like this:

How do you go about cleaning this up? Which Favorites are used? Who uses them? Can you delete them?

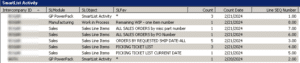

GP PowerPack has a new Tweak called SmartList Activity Tracker. It watches which Favorites are used, counts how often they are used, when, and by whom. The result looks like this:

Using this information, you can embark on a project to declutter SmartList! Keep the things that are used and get rid of the unnecessary stuff you have accumulated over the years.

MFGPowerPack 2024-02-20

Release Date: 20-FEB-2024

GP Versions: 12/14/16/18

GP PowerPack Build: 8.173

* COMPLETE INSTALLATION ROUTINE REQUIRED FOR THIS BUILD.

* New Tweak: SYS-SmartList Activity Tacker: creates an access log for SmartList Objects so you can monitor which ones are used, and which ones are not, and reduce SmartList clutter by getting rid of unused SmartLists.

* Added label to GoTo buttons for better appearance with Action Pane menus

* This release will notify POWERUSERs when there is a new version of the software available for download.

MFGImport 2024-02-19

Release Date: 19-FEB-2024

GP Versions: 12/14/16/18

MFG Import Build: 5.75

* Errors Window: fixed issue that prevented it from opening in some cases from the Routing Import window.

MFGPowerPack 2024-02-15

Release Date: 15-FEB-2024

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.233

* Fixed case sensitivity issue in the Actual Cost Rollup installation routine. If you had an installation error with the previous build and your database is Case Sensitive, drop the stored procedures below before installing this build:

— wspRollupCosts

— wspCreateBOMLev1Pending

— wspBuildBOMLev2File

* PowerATP: added Additional Menu to access PowerATP from (1) MRP Workbench, (2) PAB Inquiry, (3) MRP Quantities Query, (4) Pegging Inquiry

Dynamics GP Low Level Code Fix

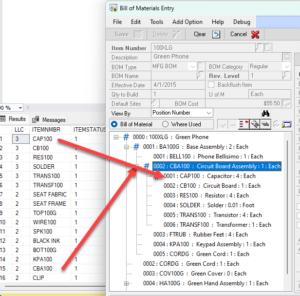

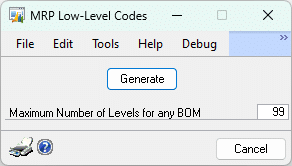

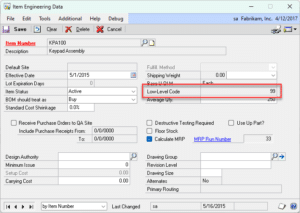

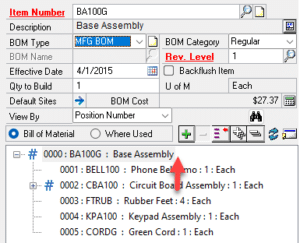

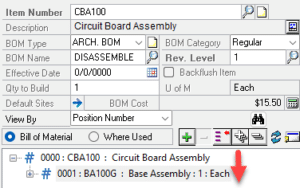

The Low Level Code (LLC) utility in GP Manufacturing calculates the lowest level at which any component is found.

For example, CBA100 is at level 2 and CAP100 is at level 3. Material Requirements Planning (MRP) uses this LLC so it knows at which level it needs to start planning (i.e. start at the “top” and work your way down).

Imagine a situation where A uses B which uses C which uses B. This is a circular Bill of Materials (BOM). Normally Dynamics GP will not allow you to create this type of arrangement. However, the LLC Utility has a bug that makes it think there are circular BOMs.

The LLC utility “Maximum Levels” setting provides a “fail safe” to address circular BOMs. If the utility runs through the A–B–C–B loop 99 times it will stop. When you look at the LLC code on Item Engineering it will show 99. An easier way to see this is to look at the Item Engineering SQL table (IVR10015).

The bug in the LLC utility is that it does not traverse straight down each BOM.

When working down 100XLG it should retrieve the specific BOM for BA100G (in this case the MFG BOM for BA100G), and then the MFG BOM for CBA100. Instead, it retrieves ALL BOMs for BA100G (i.e. the MFG BOM, ENG BOM, all CONFIG and ARCH BOMs).

This is a problem because you could legitimately have parts that can be changed into each other. In the BOM above perhaps you MAKE BA100G using CBA100, but you also sometimes DISASSEMBLE BA100G back into parts. You could use one of the Named BOM Types (i.e. ARCH or CONFIG) to store “disassembly” BOMs. Now when looking at all available BOMs you have this situation:

You use CBA100 to make BA100G, but you can take apart BA100G to “make” a CBA100.

When the LLC utility is traversing down 100XLG it sees it contains CBA100. At that point it grabs ALL BOMs and starts working down those. That creates a circular situation because it can proceed down the ARCH BOM which takes it back “up” to BA100G. It is then stuck in a circle.

WilloWare has a fix for the Manufacturing Stored Procedure in question. If you would like it, please contact our support team.

MFGImport 2024-02-01

Release Date: 1-FEB-2024

GP Versions: 12/14/16/18

MFG Import Build: 5.74

* Errors Window: update to excel export query

MFGImport 2024-01-30

Release Date: 30-JAN-2024

GP Versions: 12/14/16/18

MFG Import Build: 5.73

* Updated internal resources

* Errors Window: changes sort order on excel row from descending to ascending

MOGenerator 2024-01-30

Release Date:30-JAN-2024

GP Versions: 12/14/16/18

MOGenerator Build: 4.132

* Updated internal resources

Engineer To Order (ETO) 2024-01-30

Release Date: 30-JAN-2024

GP Versions: 12/14/16/18

ETO Build: 2.45

* Updated internal resources

MFGPowerPack 2024-01-25

Release Date: 25-JAN-2024

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.232

* Fixed issue with new build notification that was presenting the notice to users if they were in the POWERUSER group in any company database, not just the current company database (#202400003)

MFGPowerPack 2024-01-23

========== Change History ========

Release Date: 23-JAN-2024

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.231

* TimeCard: (1) fixed issue that allows a user to get out of the window without filling in all required field (#202302033), (2) fixed issue with auto-tab and auto-start/stop where the window would set both start and stop entries on the first record.

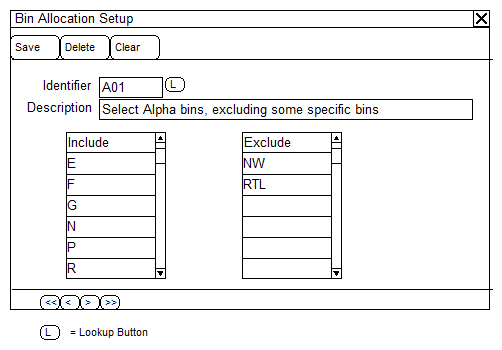

Customization CR1196 – MFG Auto-allocation from Multiple Bins

Customization CR1196

MFG Auto-allocation from Multiple Bins

Description of Need:

When Manufacturing Allocates inventory it does so only from the Default Material Issue Bin set up on the Item-Site. If there is not enough inventory in that bin, the user must manually select one or more bins to meet the required quantity.

ACME would like manufacturing to automatically allocate from an many bins as needed, provided their business logic described below.

- If the Site ID is not 0FI (zero F i ), use the default Item-Site Material Issue Bin.

- Bins starting with “2-“

- Bins starting with “3-“

- Bins starting with a letter (A-Z) but not those starting with A, B, C, D, NW or RTL

- Bins starting with a number (0-9)

- Bins starting with A, B, C or D

- Bins starting with NW

- Bins starting with RTL

In all cases a bin “starting with” “A” can also just be “A”. So “starting with A” would retrieve A, AGG, A-123, and so on.

The rules should be processed in order. First try to allocate from “2-“ bins, then if more inventory is needed (or there are no 2- bins with inventory) check the 3- bins, and so on. For each rule, if there are multiple bins with inventory (i.e. there are multiple 2- bins with inventory), allocate by starting with the smallest quantity first (this should drive the system to consume small quantities thereby reducing the number of bins containing few items).

Description of Solution:

Navigation: Tools >> Setup >> Manufacturing >> Bin Allocation Setup

This window is used to define “rules” that govern how Manufacturing will locate bin inventory to allocate.

| Field | Function |

| Identifier | Use a naming convention that considers the following. (1) Rules will be processed in Alpha-numeric order. Use a naming convention that ensures the rules are processed in the desired order. (2) Using a naming convention that leaves space between Rules so that additional rules can easily be added between them. For example, A01, B01, C01, etc allows adding A02 so it falls between A01 and B01. |

| Description | Plain text description of the rule |

| Include list | Bins will be included if the Bin begins with, or equals, the specified value. For example, entering “2-“ will retrieve Bins such as 2-A, 2-B and so on. One ore more values is REQUIRED in the Include List. |

| Exclude list | Bins will be excluded if the Bin begins with, or equals, the specified value. The Exclude List may be empty. |

As shown above, all Bins beginning with “N” will be excluded, except those beginning with (or equal to) “NW”.

The Manufacturing module allocates inventory using a stored procedure called mmopAllocateBinQuantities. WilloWare will create a modified version of that stored procedure that will use the Bin Allocation Rules to direct how inventory is allocated.

mmopAllocateBinQuantities is used to allocate inventory in bins from several locations in Manufacturing, so the proposed change to that stored procedure will affect allocation from the following windows:

- Manufacturing Order Close

- Manufacturing Component Transaction Entry

- Edit Manufacturing Order Status

- Quick MOs

- Manufacturing Order Receipt Entry

- Picklist

Assumptions/Requirements:

- The functionality described above will not work with eConnect, any software that uses eConnect, or any software that directly writes to, updates, or deletes from SQL tables.

- The functionality described above is intended for the GP Desktop client.

For information on this design, or any other WilloWare customization or product, please contact us:

MFGImport 2024-01-11

Release Date: 11-JAN-2024

GP Versions: 12/14/16/18

MFG Import Build: 5.72

* Excel Export from Errors window: fixed issue that could cause a datatype conversion error.

* Added label to GoTo buttons for better appearance with Action Pane menus

* This release will notify POWERUSERs when there is a new version of the software available for download

MOGenerator 2024-01-09

Release Date: 9-JAN-2024

GP Versions: 12/14/16/18

MOGenerator Build: 4.131

* Fixed error in projected resources calculation (WO010032 projected resources fields)

* Added label to GoTo buttons for better appearance with Action Pane menus

* This release will notify POWERUSERs when there is a new version of the software available for download.

Engineer To Order (ETO) 2024-01-09

Release Date: 9-JAN-2024

GP Versions: 12/14/16/18

ETO Build: 2.44

* Fixed error in project resources calculation (WO010032 projected resources fields)

* Added label to GoTo buttons for better appearance with Action Pane menus

* This release will notify POWERUSERs when there is a new version of the software available for download.

MFGPowerPack 2024-01-08

Release Date: 8-JAN-2024

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.230

* MO Split: Fixed issue in the split MO Scheduling routing that caused the projected values to not be recalculated correctly on the new MO (#202301689)

* Serial Number Mass Entry: (1) user is now prompted to confirm they are ready to run the import after clicking the Import button, (2) the status bar now displays “Done” when the import is complete

* Added label to GoTo buttons for better appearance with Action Pane menus

* This release will notify POWERUSERs when there is a new version of the software available for download.

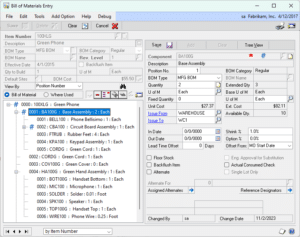

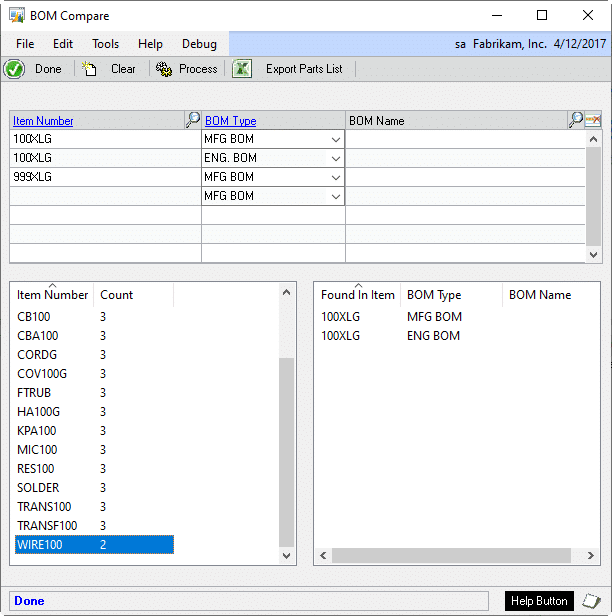

MFG PowerPack BOM Compare

BOM Compare analyzes the exploded Bill of Materials for two or more Manufacturing BOMs to create a list of common components.

Enter two or more Bills of Material in the top scrolling window. BOM Compare loads the exploded bill of materials for each item, then compares them to create a count of the components found in each of the BOMs. Selecting a component shows which BOMs contain the selected component.

MFGImport 2023-12-07

Release Date: 7-DEC-2023

GP Versions: 12/14/16/18

MFG Import Build: 5.71

* BOM Import: (1) Added Item Engineering (IVR10015) to the pre-import check for blank records validation, (2) Changed Error Log button notification method to use different icons rather than backcolor change so that it works with both Action Pane menu and Menu Bar menu display settings.

* Routing Import: (1) Changed Error Log button notification method to use different icons rather than backcolor change so that it works with both Action Pane menu and Menu Bar menu display settings.

* FULL INSTALL REQUIRED! ALL USERS MUST BE OUT OF DYNAMICS GP. This releases changes the primary key on the Error Log table.

MFGPowerPack 2023-11-30

Release Date: 30-NOV-2023

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.229

* NEW TWEAK- Item LLC Recalc: The Manufacturing LLC Utility runs for all items and can take a long time to process. Adding a component in BOM Entry forces a recalc based on that single BOM. The BOM Mass Update utility does not recalculate LLC. Additionally integrated BOMs, and SQL table updates would also not trigger an LLC calc. This tweak will automatically recalculate LLC when changes are made in the BOM Mass Update window, and it will also add an Additional Menu to Item Engineering to recalc a single item.

MOGenerator 2023-11-29

Release Date: 29-NOV-2023

GP Versions: 12/14/16/18

MOGenerator Build: 4.130

* MO Gen Core/MO Receipt Integration: added integration to WilloWare’s MFG Import that allows the MOGen Scheduler to run BOM Import and/or Routing Import prior to any of the MO Gen Core Utilities or MO Receipt Integration. When the MOGen Scheduler is run continuously it will run the MFG Import utilities once per cycle (i.e. once per minute, or whatever the polling frequency is set to).

GPPowerPack 2023-11-21

Release Date: 21-NOV-2023

GP Versions: 12/14/16/18

GP PowerPack Build: 7.172

* Requested Ship Date Rolldown: added setup option to control if manufacturing Customer Promise Date is updated (by default it is) along with In House Due Date (#202301568).

* Sales Pro Item Lookup: the window will now remember each user’s last used “View” setting (i.e. Customer Items, All Items, etc), and will reopen to that view.

MFGPowerPack 2023-11-20

Release Date: 20-NOV-2023

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.228

* Capable To Promise (CTP): added open to explode both Regular and Phantom BOMs

SpellCheck 2023-11-20

Release Date: 8-JAN-2023

GP Versions: 12/14/16/18

SpellCheck Build: 1.32

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update SpellCheck even if you are not upgrading to GP18.6 at this time.

SOPPOPMultiLink 2023-11-20

Release Date: 20-NOV-2023

GP Versions: 12/14/16/18

SOPPOPMultiLink Build: 1.11

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update SOP-POP MuiltiLink even if you are not upgrading to GP18.6 at this time.

Preactor Integration 2023-11-16

Release Date: 16-NOV-2023

GP Versions: 12/14/16/18

Preactor Integration Build: 1.20

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update Preactor Integration even if you are not upgrading to GP18.6 at this time.

MOGenerator 2023-11-16

Release Date: 16-NOV-2023

GP Versions: 12/14/16/18

MOGenerator Build: 4.129

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update MOGenerator even if you are not upgrading to GP18.6 at this time.

MFGImport 2023-11-15

Release Date: 15-NOV-2023

GP Versions: 12/14/16/18

MFG Import Build: 4.70

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update MFG Import even if you are not upgrading to GP18.6 at this time.

* BOM Import: added data validation to catch importing MFG BOM with BOM Name populated, or ARCH/CONFIG BOM with BOM Name blank.

MFGDataArchive 2023-11-15

Release: 15-NOV-2023

GP Versions: 12/14/16/18

MFGDA Build: 1.32

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update MFG Data Archive even if you are not upgrading to GP18.6 at this time.

MFGPowerPack 2023-11-14

Release Date: 14-NOV-2023

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.227

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update MFGPowerPack even if you are not upgrading to GP18.6 at this time.

* Capable To Promise (CTP): (1) fixed issue in Max Build calculation where it was using the Component BOM Qty rather than the Ext BOM Qty (#202301546), (2) changed BOM Qty to show exploded BOM Qty calculation, (3) added a dropdown to the window to change if the window calculates based on QTY Quoted or QTY Required.

LeanMFG 2023-11-13

Release Date: 13-NOV-2023

GP Versions: 12/14/16/18

LeanMFG Build: 3.57

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update LeanMFG even if you are not upgrading to GP18.6 at this time.

* MO Entry: A link has been added on the MO Entry window to access the BOM Notes

LabelLink 2023-11-10

Release Date: 10-NOV-2023

GP Versions: 12/14/16/18

LabelLink Build: 2.46

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update LabelLink even if you are not upgrading to GP18.6 at this time.

GPPowerPack 2023-11-10

Release Date: 10-NOV-2023

GP Versions: 12/14/16/18

GP PowerPack Build: 7.171

* Kit Transfer: fixed issue that can cause incorrect QTY Allocated when using Kit Transfers with In Transit Transfers (#202301473). Running IV Reconcile will correct the allocations.

Item Process Tracking (IPT) 2023-11-06

Release Date: 6-NOV-2023

GP Versions: 12/14/16/18

IPT Build: 2.21

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update Item Process Tracking (IPT) even if you are not upgrading to GP18.6 at this time.

EZImport 2023-11-06

Release Date: 6-NOV-2023

GP Versions: 12/14/16/18

EZImport Build: 1.19

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update EZImport even if you are not upgrading to GP18.6 at this time.

Engineer To Order (ETO) 2023-11-06

Release Date: 6-NOV-2023

GP Versions: 12/14/16/18

ETO Build: 2.43

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update ETO even if you are not upgrading to GP18.6 at this time.

Consulting Toolkit 2023-11-03

Release Date: 3-NOV-2023

GP Versions: 12/14/16/18

CTK Build: 2.35

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update CTK even if you are not upgrading to GP18.6 at this time.

BlanketPO 2023-11-03

Release Date: 3-NOV-2023

GP Versions: 12/14/16/18

BlanketPO Build: 1.44

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update BlanketPO even if you are not upgrading to GP18.6 at this time.

CompleteCount 2023-11-02

Release Date: 2-NOV-2023

GP Versions: 12/14/16/18

CompleteCount Build: 4.60

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update CompleteCount even if you are not upgrading to GP18.6 at this time.

GPPowerPack 2023-11-02

Release Date: 2-NOV-2023

GP Versions: 12/14/16/18

GP PowerPack Build: 7.170

* Updates for GP18.6

* The updates to internal resources apply to all supported versions of GP and include performance improvements, updates to error reporting and version management, and other enhancements. Please update GP PowerPack even if you are not upgrading to GP18.6 at this time.

Customization DS1115- WIP Cost Reversal

Customization DS1115

WIP Cost Reversal

Problem Definition:

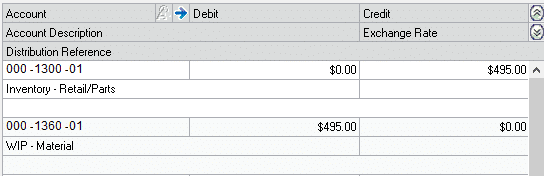

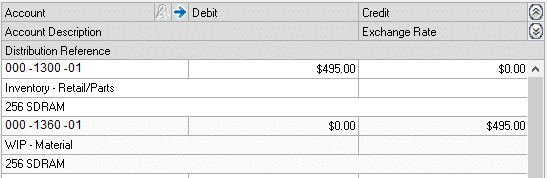

ACME builds water dispensers. Some units contain high value assemblies which are treated as capital equipment, so the value is not in an inventory account. When these assemblies are used on a manufacturing order, the normal posting process will adjust the value of the item out of the capital equipment GL account and into the WIP account of the finished good.

When Manufacturing posts the Actual Cost finished good into inventory, it uses the value in WIP to determine the cost of the finished good.

ACME needs the value of these capital items to remain in the capital equipment GL account and not get added to the final cost of the finished good.

Design Features:

Reversing WIP

The customization will monitor the Manufacturing Issue and Reverse Issue posting process. When it detects certain capital items in the resulting Inventory Adjustment, it will create and post a Journal Entry to reverse the GL effects of the Inventory Adjustment.

An Issue transaction credits Inventory and debits WIP. In this case the Inventory account will be a capital equipment account (a regular inventory account is shown below):

The reversing transaction will debit Inventory and credit WIP for the value of the inventory item (using the same GL accounts as the original transaction).

The reversing entry will also show the Item Number in the Distribution Reference field.

A Reverse Issue with a capital item will cause the transaction above to occur in reverse. Manufacturing will Debit the Inventory Account and Credit the WIP Account, and the customization will reverse that.

Assumptions/Requirements:

- The functionality described in this document is intended for the Dynamics GP desktop client. Unless specified otherwise, all testing will occur in the desktop client only. Projects created in Dexterity should have a very high level of compatibility with the Web Client, but cannot be guaranteed without explicitly including additional time in the estimate for testing in the Web Client.

MFGPowerPack 2023-10-24

Release Date: 24-OCT-2023

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.226

* Buy Picklist: Added reference to the MO# in the PO “Contract Number” field in the Purchasing Vendor Detail Entry window.

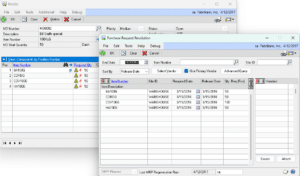

MFG PowerPack Buy Picklist

Buy Picklist is ideal for a Make to Order or Engineer to Order environment where you need to purchase the materials needed for a job, it is also useful for purchasing to address shortages on a job. Buy Picklist creates a link between the Manufacturing Picklist window and Purchase Request Resolution. With one click the Picklist requirements can be easily sent to Purchase Request Resolution where you can select Vendors and create Purchase Orders.

The link calculates the quantity to order by looking at the Item Resource Planning values (Order Quantity Modifiers), and if a Primary Vendor is assigned on the Item Quantities window it looks at the Minimum, Maximum and Order Increment from the Item-Vendor window.

MFGPowerPack 2023-10-17

Release Date: 16-OCT-2023

GP Versions: 12/14/16/18

MFG PowerPack Build: 13.225

* NEW – Buy Picklist: create purchase orders for everything on a picklist, or for shortages on a picklist.

* NEW – Tweak: Default MO Entry Date: when creating new MOs the MO Entry window defaults to a blank (zeros) date. The Default MO Entry Date tweak uses the Planning Time Fence to set the default dates to the User Date + Planning Time Fence Days from Item Resource Planning (Item-Site). Or you can customize the Tweak so use any value other than Planning Time Fence.

* FULL INSTALLATION ROUTINE REQUIRED

MFGPowerPack 2023-10-05

GP Versions: 12/14/16/18

MFG PowerPack Build: 12.224

Customization DS1452 Lot Adjustment

Customization DS1452

Lot Adjustment

Problem Definition:

ACME uses Dynamics GP lot tracking on their inventory items. Sometimes during stock counts they will find that a Lot Number is incorrect in GP for the physical inventory counted, so they need to adjust inventory to put the “correct” Lot Number in and remove the “incorrect” Lot Number. They are currently doing this manually with an Inventory Adjustment and would like a more automated way to do this.

The adjustment needs to retain the same Receipt Date, Cost, MFG Date, EXP Date and Lot Attributes.

Solution Overview:

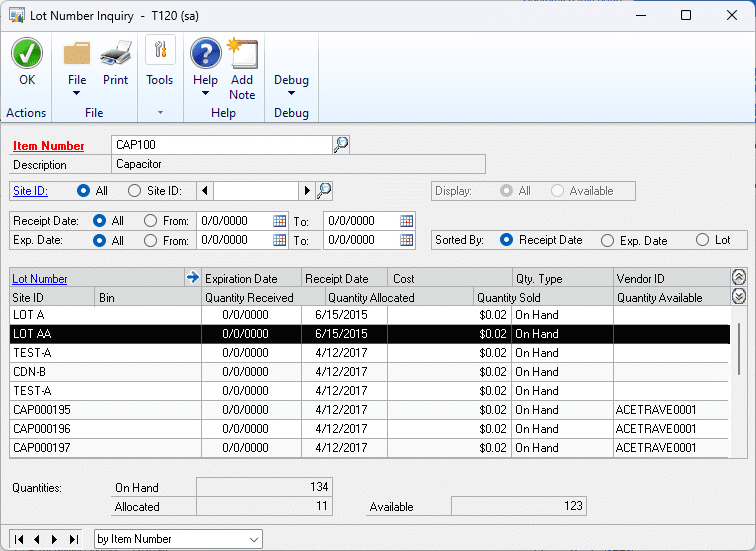

WilloWare will create a dexterity enhancement for Dynamics GP that allows users to find a lot in the Lot Inquiry window and automatically create the complete IV Adjustment to adjust the lot number.

Design Features:

Navigation: Inquiry>> Inventory>>Lots

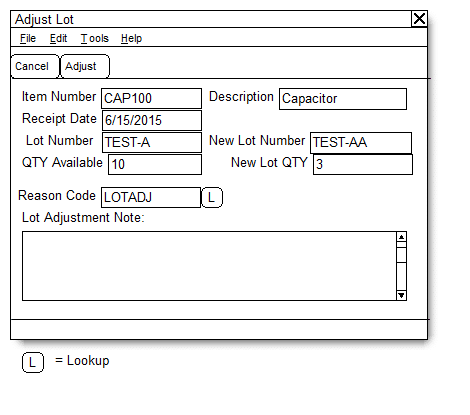

The Lot Number Inquiry window is used as a “lookup” window to locate a specific lot receipt that needs to be adjusted. Enter the Item Number and find the Lot that needs to be adjusted. Select the row as shown above, then go to Additional >> Adjust Lot.

| Field | Function |

| Item Number | Displays the Item Number |

| Description | Displays the Item Description |

| Receipt Date | Displays the Receipt Date for the Lot Number. This will be the IV Adjustment |

| Lot Number | Displays the selected Lot Number |

| New Lot Number | Enter the new Lot Number. For example, the adjustment will change TEST-A to TEST-AA |

| QTY Available | Displays the QTY Available for the Lot Number |

| New Lot QTY | Enter the adjustment quantity. This can be up to the QTY Available. New Lot QTY defaults to the QTY Available |

| Reason Code | Enter an IV Adjustment Reason Code, or select one from the Lookup. This will be used on the lines of the Inventory Adjustment. A Reason Code is required |

| Lot Adj Note | Enter text description explaining the Lot Number Adjustment. This will become the Inventory Adjustment document note. The Note is not required |

ADJUST: Click the Adjust button to create an inventory adjustment. You will be asked to confirm you are ready to adjust the lot number. If YES, the following will occur:

- And inventory adjustment will be created and saved in a Batch. The Batch ID will be up to 15-characters of the User ID.

- The Transaction Date will be set to the Lot Receipt Date. NOTE: it will be possible to create a transaction for a Closed Period. No warnings will be given, but it will not be possible to post the transaction without addressing the issue.

- The first line will be negative and adjust OUT the selected Lot and Quantity using the Site and Bin from the selected lot record.

- The second line will be positive and adjust IN the New Lot Number using the Site, Bin and Cost from the selected lot record.

- The MFG Date and EXP Date of the New Lot Number will be set based on the old Lot Number.

- If a Lot Attribute record does not exist for the New Lot, one will be created and the Attributes will be copied from the old lot. If a Lot Attribute record exists for the New Lot, it will NOT be changed based on Attributes from the Old Lot.

- If the user has security rights, the Item Transaction Entry window will open and display the transaction.

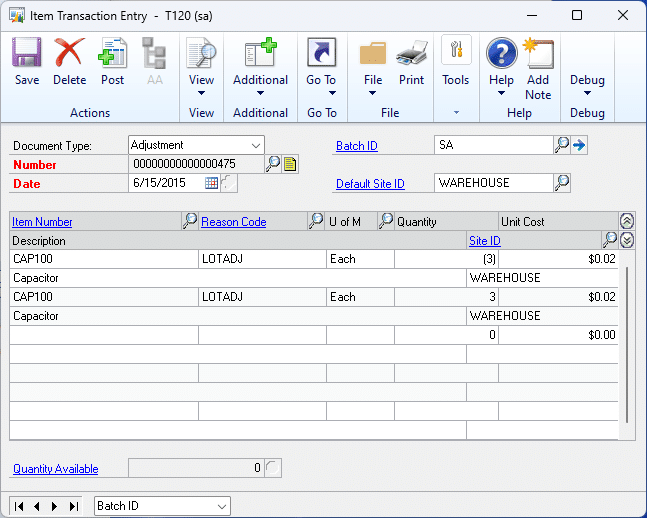

The net effect will be an Inventory Adjustment, as shown below, in and out on the original receipt date that results in a change to the Lot Number on that date, but the quantity and cost stay the same.

Assumptions/Requirements:

- The functionality described above will not work with eConnect, any software that uses eConnect, or any software that directly writes to, updates, or deletes from SQL tables.

- The functionality described above is intended for the GP Desktop client.

- National Accounts functionality is NOT used.

- Advanced Distribution functionality is NOT used.

- Unless otherwise noted in this document, reporting is not included in this estimate.

- Unless otherwise noted in this document, Word Template functionality is not addressed.

- Unless otherwise noted in this document, the enhancement will not integrate with 3rd party products. Some examples of 3rd party products would be:

- An ISV plug-in product including WilloWare products

- A dexterity customization designed by another developer

- Dynamics GP Modules including, but not limited to:

- Project Accounting

- MDA

- Analytical Accounting

- Copy functionality found in SOP, POP and Inventory

- Field Service

- Extended Pricing

- Manufacturing

For information on this design, or any other WilloWare customization or product, please contact us:

CompleteCount 2023-09-21

Release Date: 21-SEP-2023

GP Versions: 12/14/16/18

CompleteCount Build: 4.59

* Stock Count Maintenance: CompleteCount now has a replacement for the GP Stock Count Schedule window that significantly improves performance. The CC Stock Count Schedule window performs the same function as the GP Stock Count Schedule window but has been optimized for large amounts of data. Plus it has speedy filters for quickly restricting the window using a “contains” search on Item Numbers, Bins, Location Codes and Item Descriptions.

*COMPLETE INSTALLATION ROUTINE REQUIRED! This release includes a new window, CC Stock Count Schedule. Security settings will be updated during the installation to add the window.

This is a quick demonstration of the new window showing how much faster it is than the GP window even with just 300 rows.