Customization

DS1075 Secondary Vendors

Problem Definition:

ACME enters Payables invoices and checks in Dynamics GP. The invoice and check will both be entered for the Vendor (the “Primary”) but a second vendor needs to be associated with the invoice (the “Secondary”). The relationship

The Secondary vendor needs to be referenced on the check stub that is send to the Primary vendor. ACME uses Mekorma to print checks.

ACME would also like the ability to display the Secondary Vendor ID and Name on Edit List and Posting Reports

When ACME displays a vendor in the PM Transaction Inquiry – Vendor window, the scrolling window must display the invoices where the displayed vendor is the Secondary Vendor.

Controls need to be added to Payables Transaction Entry to prevent a Vendor Invoice (Document Number field) from being reused. GP currently has controls to prevent this on a per vendor basis, but ACME needs to consider by Secondary Vendor too.

Design Features:

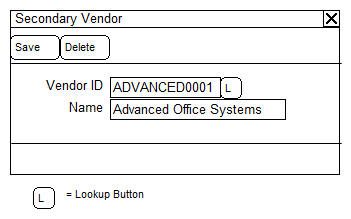

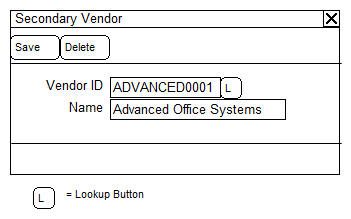

Secondary Vendor

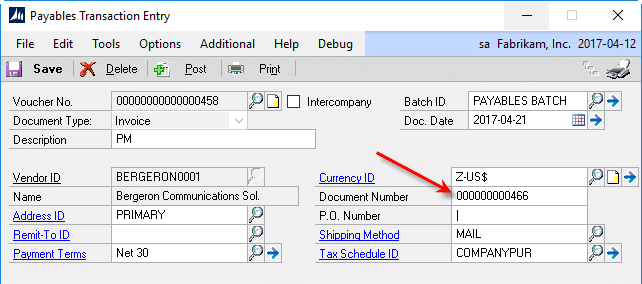

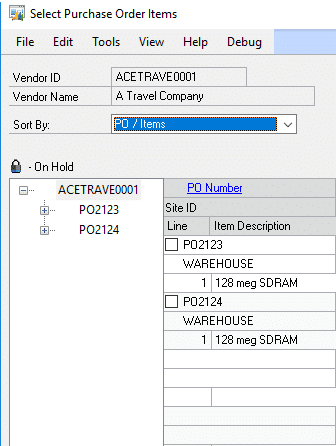

Navigation: Transactions >> Purchasing >> Transaction Entry >> Additional >> Secondary Vendor

|

Field

|

Function

|

|

SAVE

|

Saves the Secondary Vendor to the transaction.

|

|

DELETE

|

Deletes the Secondary Vendor from the transaction.

|

|

Vendor ID

|

Enter or select a Vendor ID to assign as the Secondary Vendor. The Secondary Vendor cannot be the same as the Primary Vendor.

|

|

Name

|

Displays the name of the Vendor ID

|

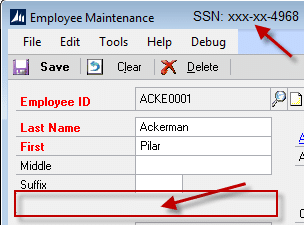

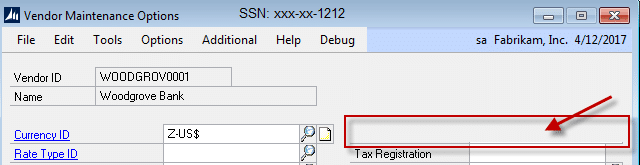

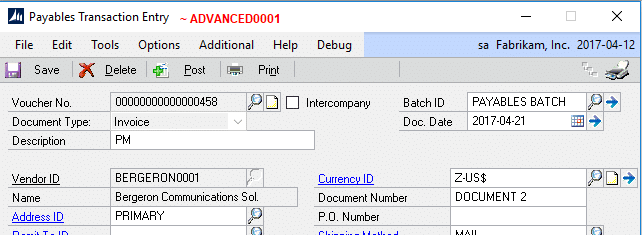

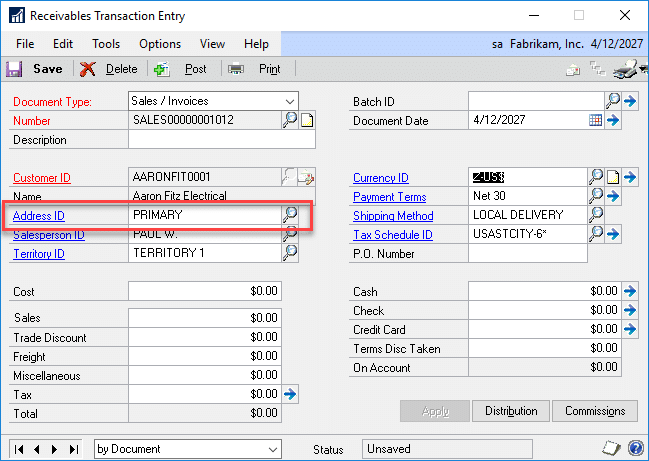

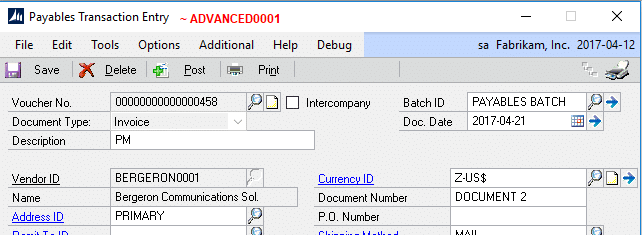

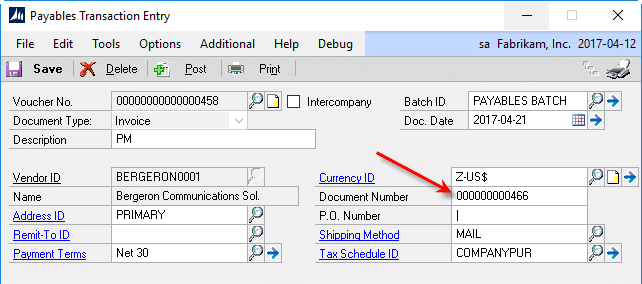

The Secondary Vendor window will be accessed from the Additional menu on the Payables Transaction Entry window. When a Secondary Vendor has been linked to the Payables Transaction, the Secondary will be displayed in the Payables Transaction Entry header (NOTE, it will not be in red in the enhancement):

The Secondary Vendor will also be visible from the title bar on the Payables Transaction Entry Zoom window, but the Secondary Vendor window WILL NOT be accessible as to prevent changing the vendor after the invoice has been posted.

Report Modifications:

Check Printing

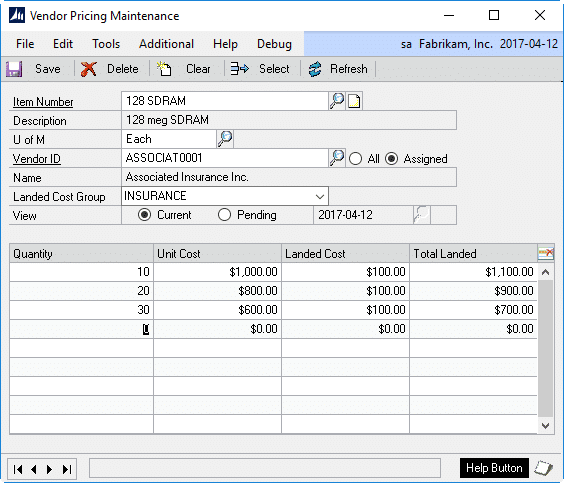

ACME uses Mekorma for their check printing and would like the Secondary Vendor Name to print on the check stub. Mekorma will provide the customization of the check stub. The following is the table format that will store the Secondary Vendor.

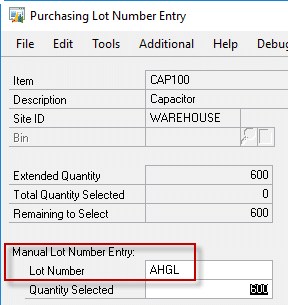

Table: wSecVendor

|

Field

|

Function

|

|

VCHRNMBR

|

*Key Field. The PM Transaction Voucher Number.

|

|

DOCTYPE

|

*Key Field. The PM Transaction Document Type.

|

|

VENDORID

|

The Primary Vendor ID of the transaction.

|

|

SecVendor

|

The Secondary Vendor ID linked to the transaction

|

* wSecVendor table will need to be joined to the Vendor Master table (wSecVendor.SecVendor to PM00200. VENDORID) in order to retrieve the Vendor Name of Secondary Vendor for the required Voucher and Document Type.

** The table name is for illustrative purposes to assist Mekorma in producing and estimate of work. Actual table name must be confirmed after project approval. Upon project approval WilloWare has agreed to provide Mekorma with a SQL CREATE and SELECT statement to use for their development and testing.

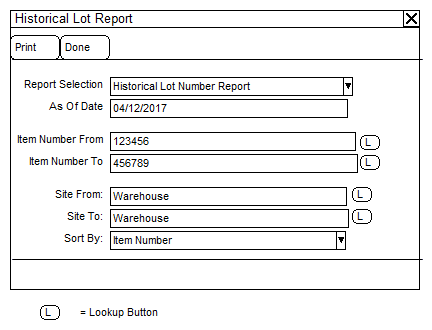

Batch Edit and Posting Reports

WilloWare will add a report writer function to the enhancement that will allow ACME to include the Secondary Vendor ID and Name to any GP report that has access to the Payables Voucher Number and Document Type via a calculated field, such as when printing an edit list or posting journal.

WilloWare will provide the report writer function as well as instructions on its use. ACME will perform all report modifications. This estimate does not include time to modify GP reports.

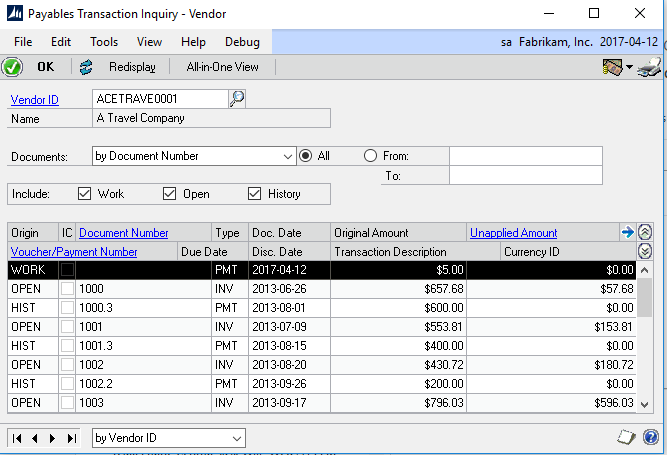

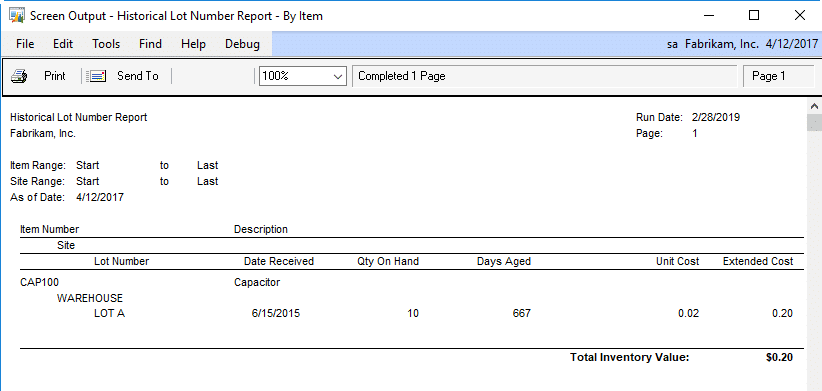

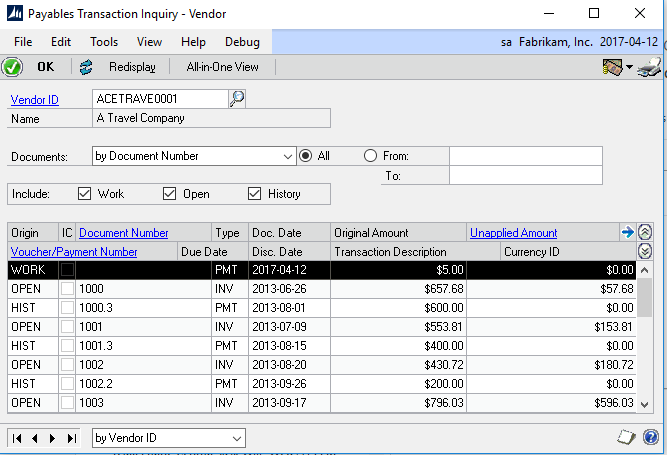

Payables Transaction Inquiry- Vendor

Navigation: Inquiry >> Purchasing >> Transaction by Vendor

The window will function as normal, meaning when a Vendor ID is entered, all documents (INV, PMT, etc.) that were entered into GP for the vendor will display in the scrolling window.

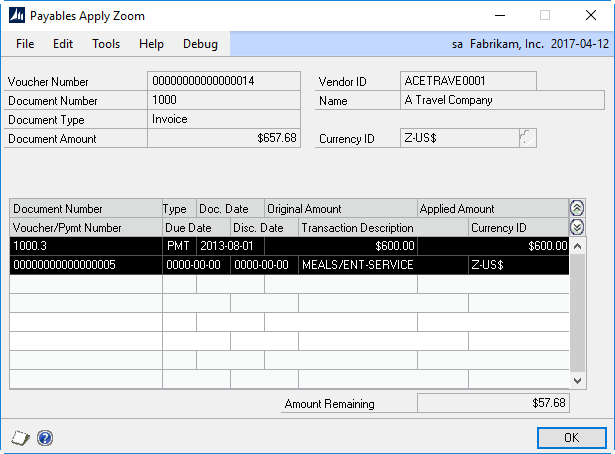

The enhancement will ADD INV transactions where the Vendor ID was selected as the Secondary Vendor. The added INV transactions must also meet the restrictions as entered. (Document Number, Date or Type From/To as well as the Include checkboxes). The Document Number and Voucher/Payment Number hyperlinks will take the user to the inquiry window for the transaction, as normal.

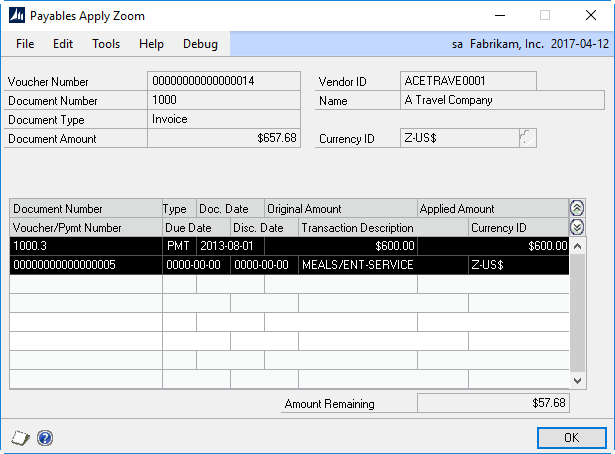

The enhancement will not display applied primary vendor PMT transactions but applied PMTs can be viewed by clicking the Unapplied Amount hyperlink to open the Payables Apply Zoom.

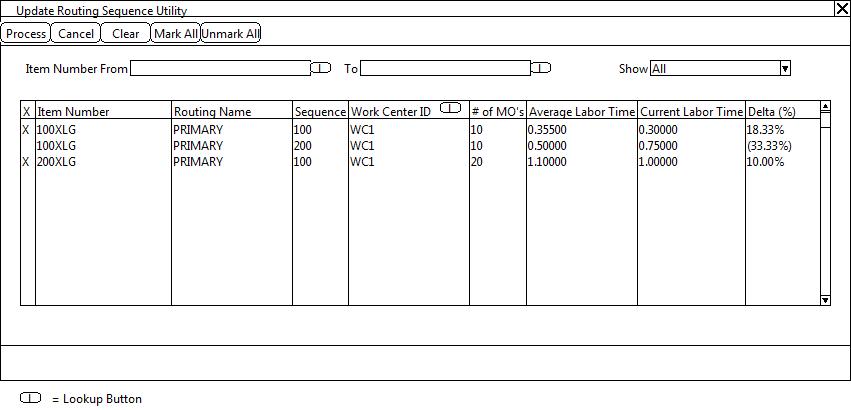

Payables Transaction Entry Controls

Navigation: Transactions >> Purchasing >> Transaction Entry >> Document Number field

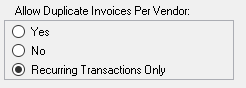

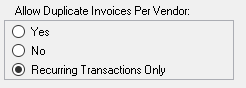

Note: The functionality described below will NOT be active if the Payables Setup Option ‘Allow Duplicate Invoices Per Vendor’ is set to YES.

Standard GP functionality will prevent the user from entering a value in the Document Number field if it previously on another voucher for the same vendor. For our purposes, GP validates the Document Number on Current Voucher for Primary Vendor to Previous Vouchers where the same vendor was the Primary Vendor. The enhancement will add the following validations, looking for duplicate document numbers on vouchers where:

-

Current Voucher Primary vendor was the Secondary Vendor on a previous Voucher

-

Current Voucher Secondary vendor was the Primary Vendor on a previous Voucher

-

Current Voucher Secondary vendor was the Secondary Vendor on a previous Voucher

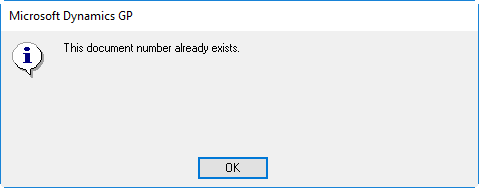

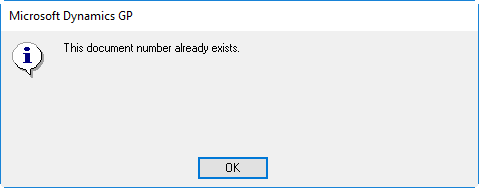

If any of the additional validations fail, the user will be presented with the message:

Assumptions/Requirements

The functionality described in this document is intended for the Dynamics GP desktop client. Unless specified otherwise, all testing will occur in the desktop client only. Projects created in Dexterity should have a very high level of compatibility with the Web Client, but cannot be guaranteed without explicitly including additional time in the estimate for testing in the Web Client.

For information on this Design Spec, or any other customization or product, please contact us at:

//willoware.com/contact-me/