Customization

CR1407

ITT Visibility to MRP

Description of Need:

ACME uses Dynamics GP Manufacturing.

They need to have full visibility to inventory balances, supply/demand and movements throughout the system. They use In-Transit Transfer documents.

In-Transit Transfer documents are not visible to MRP. ACME requires an enhancement that will provide them with visibility to both the demand and supply requirements of unshipped and/or unreceived ITT’s.

Description of Solution:

In-Transit Transfers: Visible to MRP

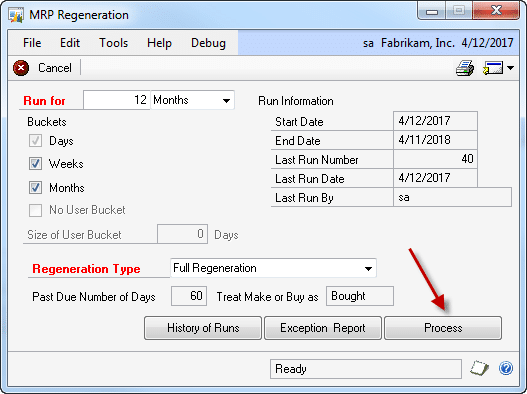

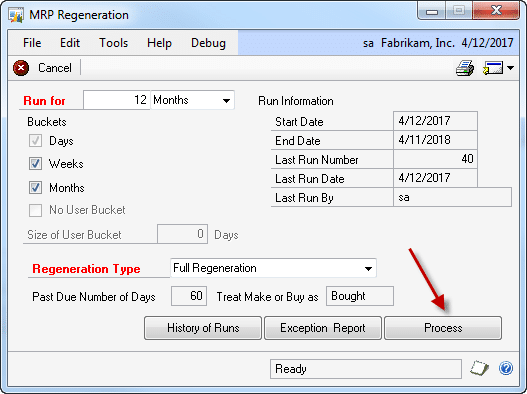

Please Note: The Regeneration Type must be set to Full Regeneration on the MRP Regeneration window. The enhancement will NOT function properly if this setting is changed to Net Change.

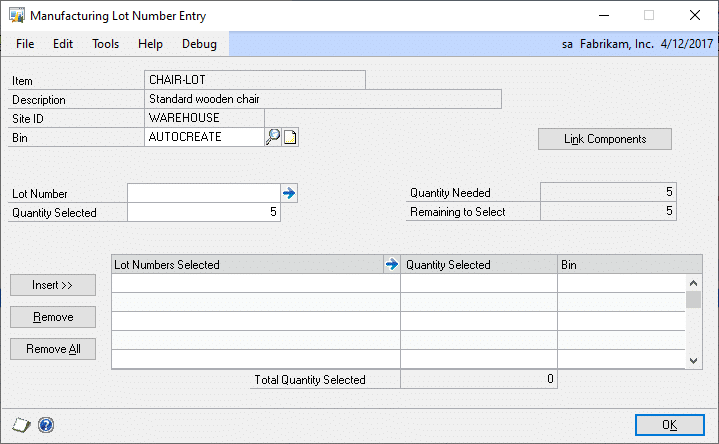

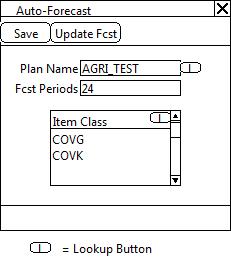

The user must manually click the PROCESS button on the MRP Regeneration window to run MRP. Clicking the PROCESS button will run the following processes prior to the MRP Regeneration process. The processes described below create/maintain “bogus” planning documents that make ITT supply/demand visible to MRP:

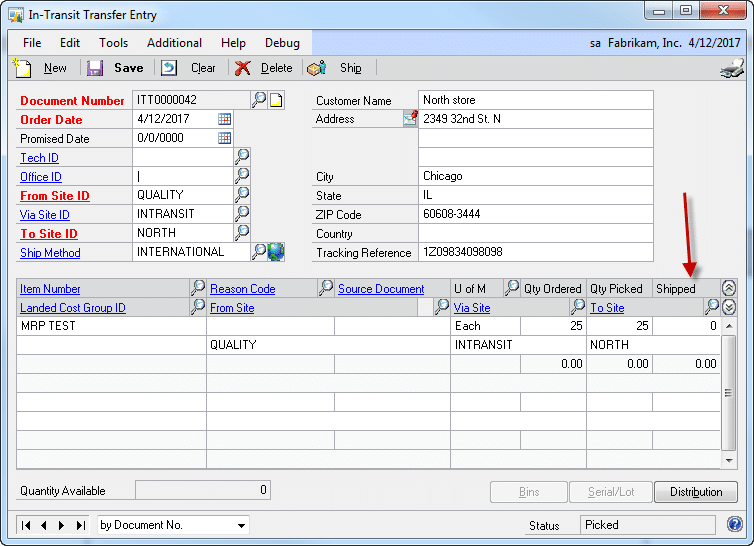

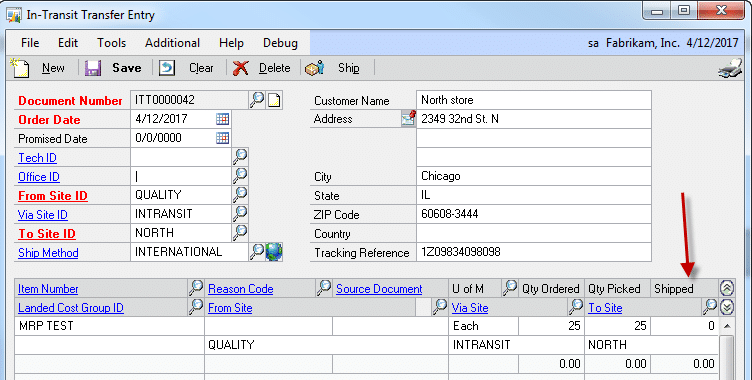

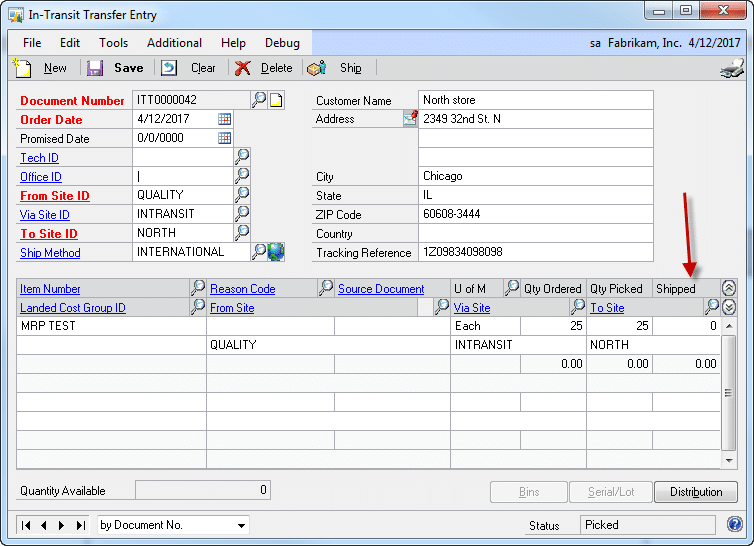

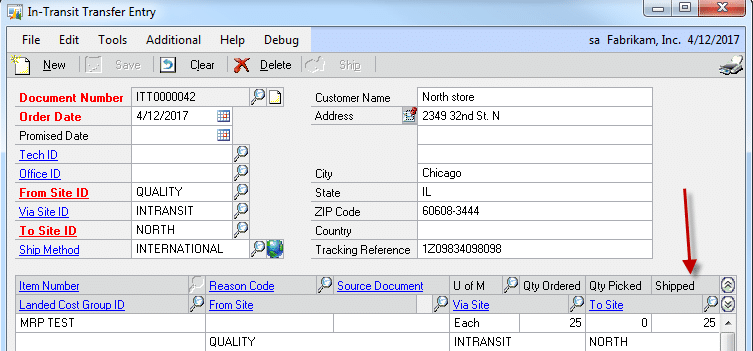

- Review unshipped quantities on In-Transit Transfer (ITT) documents to mimic DEMAND. In the ITT example below, there are 25 pieces of item MRP TEST, which have been entered on the ITT document to be supplied from Site QUALITY and shipped to Site NORTH via the INTRANSIT Site. This quantity has NOT yet been shipped.

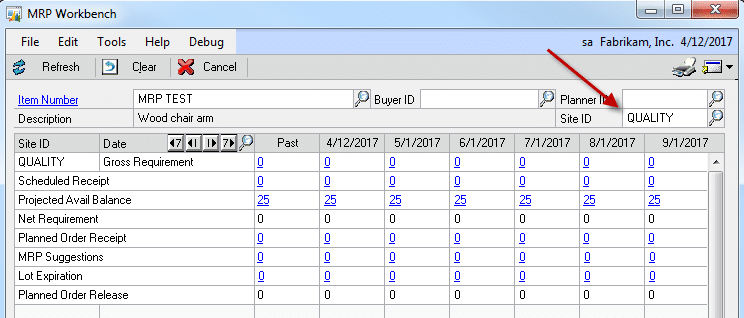

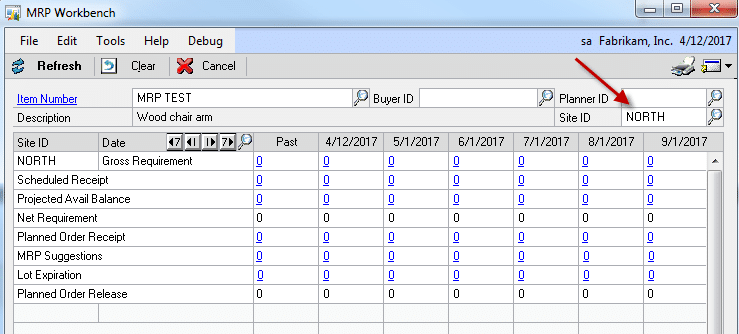

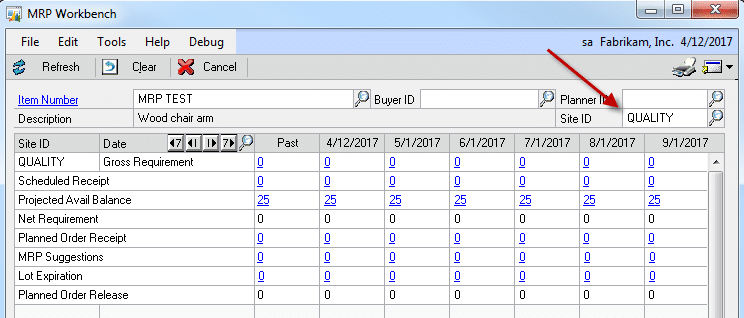

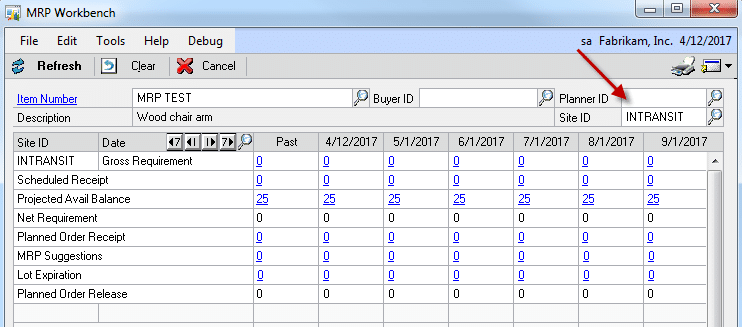

Even though the 25 pieces are allocated to the ITT document, they still show as being available to site Quality as viewed through the MRP Workbench:

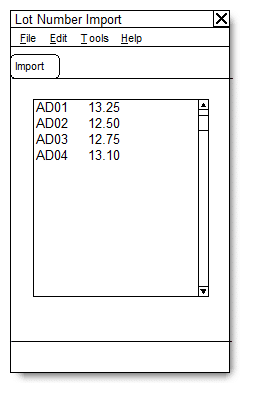

To simulate demand, the enhancement will create a dummy Manufacturing Order and Picklist. The Manufacturing Order number will be set to Z-INTRANSIT. The Manufacturing Order Item Number will be set to INTRANSIT. The Routing will be set to INTRANSIT. (This Item does not need to be an Item in the Item Master. This Item does not need to have a MFG BOM or MFG Routing assigned.) The Manufacturing Order will be set to status OPEN and its PICKLIST will be built.

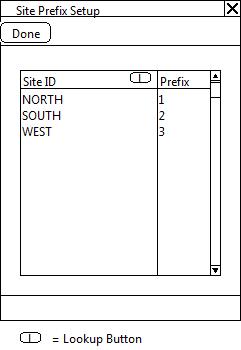

The Manufacturing PICKLIST will contain the unshipped ITT requirements. Each required Item Number/Site combination will appear as a single line item on the PICKLIST. The sum of the requirements for each Item Number will populate the Required Qty field. The PICKLIST Items/Quantities will NOT be allocated. The PICKLIST Required Date will be set to the System Date. The PICKLIST Items/Quantities will be set to Backflush. The ISSUE FROM Site on the PICKLIST will be set to the ITT’s From Site ID. In the example above, because the ITT has not yet been shipped, the ISSUE FROM Site would be set to QUALITY.

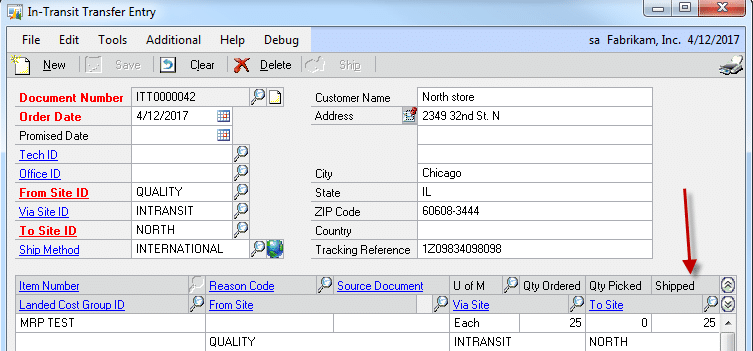

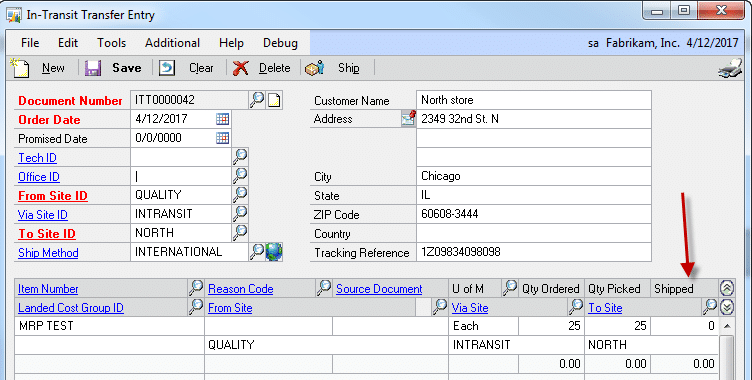

- Review shipped quantities on In-Transit Transfer (ITT) documents to mimic DEMAND. In the ITT example below, there are 25 pieces of item MRP TEST, which have been entered on the ITT document to be supplied from Site QUALITY and shipped to Site NORTH via the INTRANSIT Site. This quantity HAS BEEN shipped.

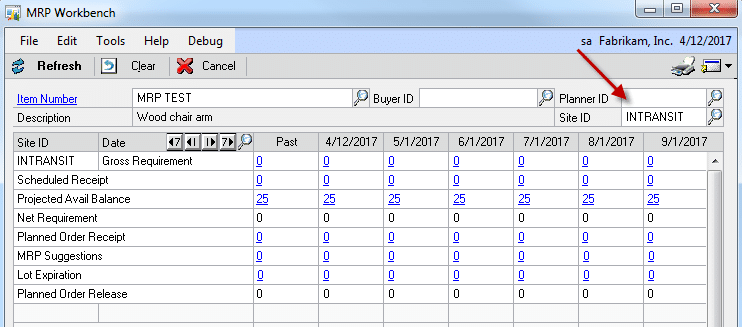

Even though the 25 pieces are allocated to the INTRANSIT Site from the ITT document, they still show as being available to site INTRANSIT as viewed through the MRP Workbench:

The enhancement will add these demand lines to the Manufacturing Picklist as described in #1 above. However, for shipped lines the following alteration will be made:

-

The ISSUE FROM Site on the PICKLIST will be set to the VIA SITE ID. In the example above, because the ITT has been shipped, the ISSUE FROM Site would be set to INTRANSIT.

- Review shipped and unshipped quantities on In-Transit Transfer (ITT) documents to mimic SUPPLY. In the ITT example below, there are 25 pieces of item MRP TEST, which have been entered on the ITT document to be supplied from Site QUALITY and shipped to Site NORTH via the INTRANSIT Site. This quantity has NOT yet been shipped.

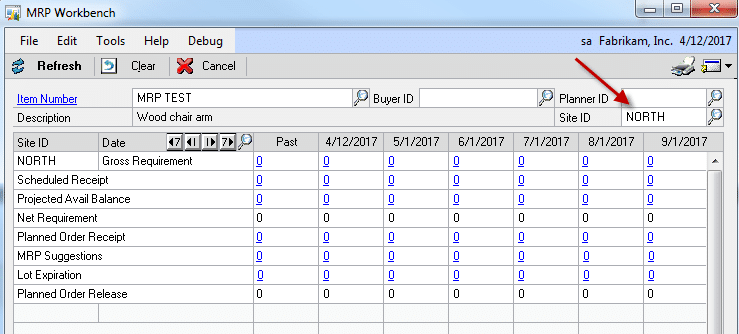

These 25 pieces are NOT visible as supply to Site ID North as viewed through the MRP Workbench.

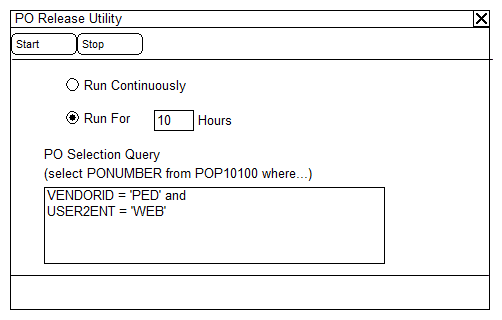

Even when the ITT document has been shipped, MRP still does NOT recognize the supply coming to the final destination Site ID. To simulate supply, the enhancement will create a dummy Purchase Order which will include both shipped and unshipped ITT quantities. The Purchase Order number will be set to Z-INTRANSIT. The Purchase Order will hold the following detail:

- Purchase Order Date: Will be set to the System Date

- Vendor ID: INTERNAL. (The enhancement will NOT validate that this Vendor ID exists. It is the responsibility of ACME to ensure that the Vendor ID is setup within Dynamics GP.)

- Currency ID: Company’s Functional Currency

- PO Status: RELEASED

The PO Lines will contain the following detail:

- Item Number: Item Number from the ITT Record

- Quantity: (Qty Ordered – Qty Received)

- U of M: UOM from the Requisition record

- Unit Cost: $0.00

- Site ID: To Site from the ITT record

- Required Date: Promised Date of the ITT Document

- Current Promised Date: Promised Date of the ITT Document

- PO Line Status: Set to RELEASED

- Vendor Item Description: Tracking Reference of the ITT Document

- Ship Method: Ship Method of the ITT Document

Please Note: If the Item Number/Vendor ID assignment does not already exist, the enhancement will auto-create the link.

Internal ACME Process Controls Are Required:

-

Users should NOT allocate parts, issue parts, receive or close the Z-INTRANSIT Manufacturing Order. The Manufacturing Order should NOT be utilized in actual Manufacturing Processes. The enhancement will NOT prevent users from doing any of the above.

-

Users should NOT copy, receive, cancel, delete, void, print, invoice or close etc. the Z-INTRANSIT Purchase Order. The Purchase Order should NOT be utilized in actual Purchasing transactions. The enhancement will NOT prevent users from doing any of the above.

Assumptions/Requirements:

-

The functionality described above will not work with eConnect, any software that uses eConnect, or any software that directly writes to, updates, or deletes from SQL tables.

-

The functionality described above is intended for the GP Desktop client.

-

National Accounts functionality is NOT used.

-

Advanced Distribution functionality is NOT used.

-

Unless otherwise noted in this document, reporting is not included in this estimate.

-

Unless otherwise noted in this document, Word Template functionality is not addressed.

-

Unless otherwise noted in this document, the enhancement will not integrate with 3rd party products. Some examples of 3rd party products would be:

-

An ISV plug-in product including WilloWare products

-

A dexterity customization designed by another developer

-

Dynamics GP Modules including, but not limited to:

-

Project Accounting

-

MDA

-

Analytical Accounting

-

Copy functionality found in SOP, POP and Inventory

-

Extended Pricing

For Information on this customization, or any other WilloWare customization or product, please contact us:

//willoware.com/contact-me/