We were busy in 2019 writing software for you! A major task was preparing new releases of all of our products for “GP Next”. We also added 28 NEW features across 9 of our products!

Below is a recap of the NEW functionality added to our products in 2019.

Planned Release Wizard: This utility will calculate and create a number of releases, such as creating a release on the first Monday of every month. It can create planned releases using a fixed quantity until the Control Quantity is met, or, it can divide the Control Quantity evenly over releases in a specified time frame.

Auto-Firm Releases Utility: This utility will automatically create Firmed Releases when the Required Date meets selection criteria. Releases can be created before the Required Date by using the Vendor Lead Time and/or Purchasing Lead Time.

ExcelLink: Extended the setup option “Require Starting Count Before Printing Tags” to Exporting the count to Excel. If the option is NOT marked you will be able to select an unstarted count in the Excel Link window and export it to Excel.

Lot Reconciliation: When submitting Tags a new routine “allocates” the total counted quantity of a Lot Number across the available receipts of a Lot Number (assuming there are multiple receipts of the same Lot Number). Previously the module attempted to “consolidate” split receipts by putting all of the counted quantity onto one lot receipt record and zeroing the others. The new routine eliminates the potential to create a cost variance even through the total count matches the captured quantity. It handles the valuation methods as follows:

** LIFO: it counts forward from oldest receipt to newest so any shortages come out of the most recent recent (the LIFO receipt)

** FIFO: it counts backwards from newest receipt to oldest so any shortages come out of the oldest receipt (the FIFO receipt)

** AVG is treated like FIFO

Start No Item Count: A new Additional Menu option has been added to the Stock Count Schedule window that allows starting a Count that contains no Items. This may be used when recording counts in Excel. The Excel Import will add “new” items to the count during the import process.

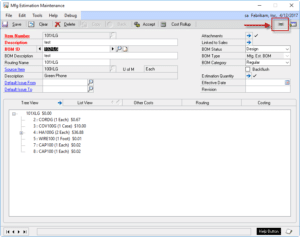

Added a new GoTo menu item “Create MO”. The Mfg Estimate window can now create a Manufacturing Order for the Item on an Accepted status estimate. If the Estimate is linked to a Sales Line, it will link the MO to the Sales Line.

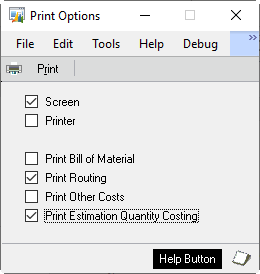

Added new reports for Estimated Quantities, Estimation Router, and Other Costs.

Added new Setup options for Routing Sequence Increment and Sequence Number Pad. The Routing Sequence Increment will default to the Manufacturing Setup value for “Sequence Spacing”, and if that is not set up (or is zero), it will default to 10 but the default can be changed. The Pad adds leading zeros to the Routing Sequence Number, so a Pad of 4 would result in “0010”, “0020”, “0030”, etc.

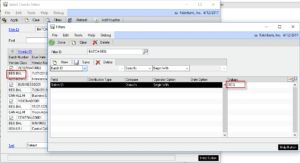

Added a new Query window: a GoTo button on the EZ Import Inquiry windows provides direct access to query the EZ Import tables using the new Query window. For example, from the EZ Import Sales Inquiry window, select GoTo >> View Sales Lines, and the query window will show all of the data in the Sales Lines table for the selected Sales Order. The Query window provides a quick way to see all of the “extra” data associated with a record that is not visible on the Inquiry windows.

POP-Tweak: Purchasing Distributions Override: This Tweak previous contained two separate functions– “PURCH Distributions Override” and “PURCH Distributions By Line”. Th second is now split out into a separate Tweak (POP-Tweak: Purchasing Distributions By Line). When Purchasing Distributions By Line creates the new distributions, it previously populated the GL Reference with the PO Line’s Item Number. A new setup option allows choosing to fill the Reference field with (1) Item Number, (2) Item Description, (3) Vendor Item Number, and (4) Vendor Item Description. If you currently have Purchasing Distributions Override, the new Tweak “Purchasing Distributions By Line” will be enabled automatically.

Shortage Inquiry: NEW-when zooming to a Sales Transaction the window will automatically scroll so that the selected short item is displayed at the top of the scrolling window.

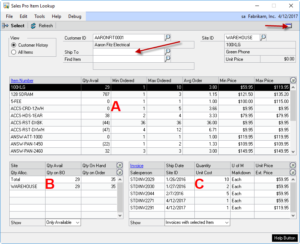

SalesPro Item Lookup: (1) Added Ship To Address to the window so that Customer Item Sales can be restricted by Ship To Address, (2) The GoTo button options are now dynamically added based on products installed and user security so it only displays options available to the user, (3) Added a Customer-Items view.

idModifier: We did a complete redesign! idModifier can now be “trained” to update/modify virtually any string (ID) field in core GP tables, 3rd Party Product tables, and custom tables. When creating a new Update ID, idModifier will search the database for a sample value (i.e. AARONFIT0001). It identifies all of the tables/fields that contain the sample. The search feature allows it to locate data in 3rd party tables, and to identify all of the different field names used to store the data (i.e. CUSTNMBR, CPRCSTNM, Bill_To_Customer, etc).

SOP Tweak: Require Customer-Item: this tweak prevents sale of an item if an Customer-Item record does not exist. This Tweak can be used to enforce a rule that requires customers to be approved to purchase items, or when they should only purchase certain items, such as private label inventory.

LoginMonitor: Added new functionality called Reserved Seats, which allows reserving a certain number of logins per User Class. For example, the User Class ADMIN could have 2 seats reserved. If the total user license count is 30, reserving 2 will make GP behave as if there are only 28 seats available for non-ADMIN users.

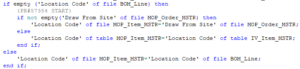

SOP Rules: (1) Added a new Rule called “Location Default by Document ID”. This Rule automatically sets the Sales Transaction Entry Location Code based on the Document ID. (2) The option to lock the Location Code field that is available with the three different SOP Rules that default the Location Code was previously only applied to the Sales Transaction Entry scrolling window. It now also locks the Location Code on the Item Detail Entry window. (3) Previously the SOP Rules functionality was always enabled if a Rule had been defined, regardless of whether or not SOP Rules was marked as “enabled” in the main GP PowerPack Setup window. All SOP Rules functionality now enables/disables based on the Setup checkbox.

Added support for label printing Automation modules. Several labelling software packages now have a server-based service for printing labels. This allows LabelLink to quickly send a label printing task to a dedicated PC, freeing-up the user’s computer to resume work while labels print.

On the LabelLink window, we added a “show” drop-down to control whether the window shows All Items, or only Items assigned to the selected label (Items can now be assigned to a label in Item-Label Setup).

Item Label Setup includes a SmartList import wizard to automate mass assignment of Items to a Label.

MO Doc Type Setup: Added two new options, “Disassembly Wizard: Remove Non-IV Items” and “Disassembly Wizard: Reverse Non-IV Costs”. The first option will cause the Wizard to create a Disassembly MO that does not include any non-inventory type items. The second option will cause the Wizard to add non-inventory type items to the Outputs tab and then during posting to create a non-inventory Journal Entry that reverses the debits/credits from the original MO.

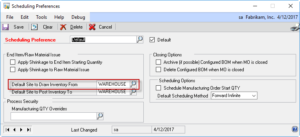

Capable to Promise (CTP): Added integration to SOP Entry and SOP Inquiry. CTP can pull in a selected item, or all items, from a Sales Transaction.

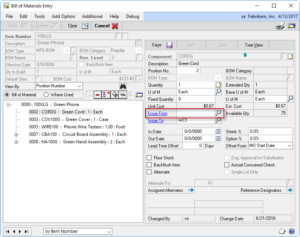

BOM History Inquiry: This new tool is a “most recently used” list for GP Manufacturing BOM Entry and BOM Inquiry. Also, it adds a hot key (CTRL + Z) to zoom to a selected subassembly. Use CTRL+Z instead of the “Select Item” button on the BOM windows. “Select Item” only works when zooming to a subassembly that has the same BOM Type & BOM Name as the Parent Item (i.e. if the Parent is a MFG BOM and the child is an ENG BOM, it will not zoom to the ENG BOM). The CTRL+Z zoom will load any selected subassembly and as BOMs are viewed they are recorded in the new BOM History window. To return to any previously viewed BOM, simply double-click on it in the BOM History window.

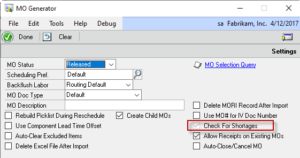

MO Split: added a new setup option to choose what the Suffix Separator is. Previously the module was hard-coded to use a DASH (i.e. MO00123-001). If MOSplit is already in use, installing this build will detect that and automatically update MO Split Setup to use a DASH as the seprator. Setup will allow using any single character as the separator. This change also addresses a conflict between MOSplit and WilloWare’s MO Generator “Create Child MOs” utility, which also uses a DASH.

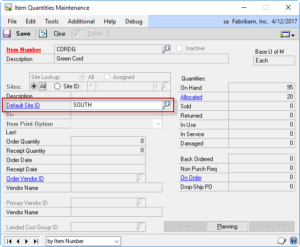

Item Copy: (1) the window now remembers the “Zero Standard Cost” setting rather than defaulting to enabled. “Zero Standard Cost” setting has been moved off the header section of the window and is in now under “Item Maintenance” (2) Performance improvements, (3) Under “Item Price List Maintenance” added a new option to zero the price list after copying it. (4) Routing Map now creates a default mapping for the primary routing using the Destination Item Number as the Routine Name if no mapping is provided, (5) The Routing Map now clears after copying an item, (6) Routing Map now has options for how it creates the Routing Name. Under the “Routing” option, click the image next to the “Default Routing Name” setting to change the default between Destination Item Number and Source Routing Name (7) Under “Item Currency Maintenance” added a new option to zero List Price (8) The installer will now add a stored procedure to the database (wspItemCopyPost) that will run after all other copying tasks. The stored procedure can be edited to include any custom ‘post copying’ updates that are needed.

PowerATP: Holds column now shows the Hold indicator for Purchase Orders, Manufacturing Orders, Picklists, and Service Calls, in addition to Sales Transactions.

NEW MFG Tweak: Purchase Request Resolution Goto MRP Workbench. Adds a menu item to the Goto button on the Purchase Request Resolution window that provides access to the MRP Workbench window. MRP Workbench will open with the Item-Site Restriction set based on the row selected in the PRR window.

NEW MFG Tweak: Create default SOP-MOP Links. When using SOP Copy to create a new Sales Document, or add lines to a Document, default (IS010001) records will be created during the copy routine.

MO Receipt Integration: added an option to check for component shortages before attempting to post the receipt. This will be enabled automatically if the Inventory Module option to override shortages is NOT marked. If Inventory allows overrides, checking for shortages in MORI will be optional.